MISCELLANEOUS

1mm Ferrules.

Ferrules

are solid terminators for multi-strand wire. They are used where the wire

is connected to a screw or spring clamping terminal. The solid pin of the

ferrule provides a much better termination in the screw terminal than bare

wires.

Note that

applying solder to the end of the wire in order to create a solid pin is

not recommended. The contact point with the connector is small and the

solder is liable to deform, especially if the connection is heated, and as

a result the wire loosens in the connector. Also, any bending or vibrating

force is concentrated at the point where the solder finishes, creating a

potential weak point. Ferrules overcome this problem.

Note that

applying solder to the end of the wire in order to create a solid pin is

not recommended. The contact point with the connector is small and the

solder is liable to deform, especially if the connection is heated, and as

a result the wire loosens in the connector. Also, any bending or vibrating

force is concentrated at the point where the solder finishes, creating a

potential weak point. Ferrules overcome this problem.

Ferrules also reduce the risk of a stray strand of wire escaping from the

screw terminal and shorting against an adjacent connector. When this

happens to a fine strand there is a risk of fire occurring before the fuse

blows.

Ferrules are typically crimped to the wire in order to ensure a solid

connection. A common form of ferrule is a tube which is crimped around the

wire to form the solid pin. However this does not work well for very small

ferrules.

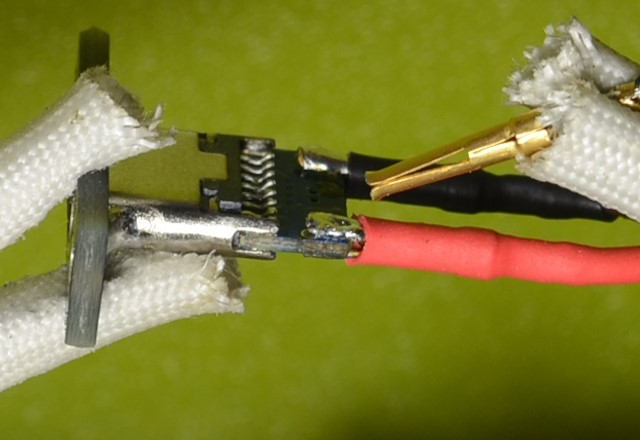

A suggestion for very small ferrules is to use the pins from a male

solder-tail D-type connector, as commonly used for serial data

cables. The connector can be disassembled by folding out the tabs of the

shield and separating the molding pieces that secure the pins. The pins

then fall out.

The pins are exactly 1mm in diameter, and fit small screw and spring-contact

connectors very well. The soldered area is about 6mm long and provides a

solid connection for the wire. It is not subject to clamping pressure from

the connector so the soldered joint remains solid. The portion beyond

the connection pin can be covered with heatshrink, which helps to eliminate

a flexing point.

Header Supports.

When soldering multiple rows of headers to modules it is important to get

them properly aligned, or they will not fit the breadboard properly and

may break a solder joint when forced. In order to align rows

of headers correctly before soldering, insert several rows of pins across

the headers. These extra pins will ensure that the headers are

parallel and upright, and will also provide a convenient base for holding

the assembly during soldering.

CNC 3018 touch sensor block.

A precision 6mm block with wire connection for the height sensor input of

a 3018 CNC machine.

The

economy versions of these machines come with a controller that supports

height sensing, but no sensor. The purpose of the sensor is to allow

the operator to define the zero level for the work surface. This can

be done by eye and feel, but a simple sensor that detects the circuit

between the tip of the milling bit and the sensor surface simplifies the

procedure considerably.

The

economy versions of these machines come with a controller that supports

height sensing, but no sensor. The purpose of the sensor is to allow

the operator to define the zero level for the work surface. This can

be done by eye and feel, but a simple sensor that detects the circuit

between the tip of the milling bit and the sensor surface simplifies the

procedure considerably.

The usual approach is to use a small piece of angle aluminium. The

problem is that the thickness is not precise, and it can be difficult to

get a reliable touch confirmation. The precision 6mm steel block

used here sits firmly on the work surface. It happens to have a

second hole through the middle which conceals that soldered connection

from the securing wire to the flexible connecting wire, and a piece of

heatshrink adds a little additional support to the solder joint. A 0.8mm

female header connects through to the controller board (there is a

matching wire running from the controller to the spindle).

Using a steel block has the added advantage that it can be stored against

a magnet that has been screwed or glued to the frame at a convenient

point.

Proto-board Table Saw

Many projects require pieces of prototyping board, either

for the actual prototyping or as the finished item, so cutting up pieces

of board is a common task. A cut-off disk on a Dremel tool does

this, but using it freehand is not always easy, and it's actually bigger

than is required. This little project re-purposed a small DC motor

(probably from a printer) by combining it with a collet, an arbor and a

cut-off disk in a 3D-printed mount to create a miniature table saw that

cuts straight edges through protoboard easily. It likely would find other

uses that projects require. The motor is an 18V 1.2A Tamagawa

TS3062N1 running at between 3,000 and 5,000 RPM. It is powered with

a laptop plugpack. The main shaft is plain and takes a collet. The rear

shaft is threaded, and in this case has been mounted with a grinding wheel

which can be used to clean up the edges of the cut. It is mounted using

the original mounting plate at the front: If this plate is missing the

printed base would need to be extended up to the holes adjacent to the

shaft, and the screws would have to be extended slightly to accomodate a

thicker support.

Many projects require pieces of prototyping board, either

for the actual prototyping or as the finished item, so cutting up pieces

of board is a common task. A cut-off disk on a Dremel tool does

this, but using it freehand is not always easy, and it's actually bigger

than is required. This little project re-purposed a small DC motor

(probably from a printer) by combining it with a collet, an arbor and a

cut-off disk in a 3D-printed mount to create a miniature table saw that

cuts straight edges through protoboard easily. It likely would find other

uses that projects require. The motor is an 18V 1.2A Tamagawa

TS3062N1 running at between 3,000 and 5,000 RPM. It is powered with

a laptop plugpack. The main shaft is plain and takes a collet. The rear

shaft is threaded, and in this case has been mounted with a grinding wheel

which can be used to clean up the edges of the cut. It is mounted using

the original mounting plate at the front: If this plate is missing the

printed base would need to be extended up to the holes adjacent to the

shaft, and the screws would have to be extended slightly to accomodate a

thicker support.

The arbor shaft is located in a pair of 8mm ball bearings. The ones

selected for this project had a lip on one side which enabled firm

mounting in the frame, but the screwed cap is actually firm enough to hold

plain bearings easily. The bearing cap could be extended to provide

a much larger table surface, but it has not been found necessary as

yet. If it was extended then supports would probably required from

the base. The screws for the bearing cap were specially selected for the

shallowness of the head, to enable a very shallow countersink.

The finished unit has a socket for the pluckpack mounted on the base, and

the motor wiring connected to the socket. An on-off switch could be

added. A reversing switch is also possible, to allow both left- and

right-handed use.

IDC Cable Clamping

Jig

It is

possible to make up IDC cables without the need for a special clamping

tool. This jig is used to clamp the ribbon cable in the connector,

with both the cable and connector located in the jig so that the whole

assembly can be placed in a vice and clamped. The crosswise groove

accommodates the head of the connector, while the lengthwise groove

accommodates the cable. There are four inserts set into the jig so

that a clamp for the cable can be used, but this is often not

necessary. With the connector pushed into its slot, the cable laid

through the connector in the groove, and the cable clamp screwed down (if

required), the whole assembly is then positioned in the vice while being

held by the cable, and the vice tightened down. The completed unit

can be removed from the jig by pushing from the hole in the bottom.

The cable is then folded back over the header and the retaining bar pushed

on (this might also require pressure from the vice, at it is a very tight

fit).

It is

possible to make up IDC cables without the need for a special clamping

tool. This jig is used to clamp the ribbon cable in the connector,

with both the cable and connector located in the jig so that the whole

assembly can be placed in a vice and clamped. The crosswise groove

accommodates the head of the connector, while the lengthwise groove

accommodates the cable. There are four inserts set into the jig so

that a clamp for the cable can be used, but this is often not

necessary. With the connector pushed into its slot, the cable laid

through the connector in the groove, and the cable clamp screwed down (if

required), the whole assembly is then positioned in the vice while being

held by the cable, and the vice tightened down. The completed unit

can be removed from the jig by pushing from the hole in the bottom.

The cable is then folded back over the header and the retaining bar pushed

on (this might also require pressure from the vice, at it is a very tight

fit).

The obvious drawback of the device is that a different jig is required

for each size of connector, but they are easy to design and print, and

most projects use only one or two widths of cable.

Tip!

When multi-core ribbon cable is stripped down to the required number of

cores the red stripe marking pin one is lost. It can be

recovered using a broad-tipped permanent marker pen. With the pen

tip pushed gently vertically onto the edge of the cable and then run along

the length of the cable, a very neat edge marking can be achieved.

The width of the pen tip is sufficient to allow it to overlap slightly

around the edge of the ribbon cable, and produce a nice even line down

each side.

Male-Male Adapter

A 3-pin 90-degree header, with the centre pin removed, makes a simple

male-to-male 2-pin adapter that is sized correctly for the 5mm screw

connectors commonly used for power connections. A straight-pin header

would also work in the same way. The pin can usually be removed

using needle-nose pliers, but in some cases the header may require gentle

heating in order to remove the pin without risk of breaking the strip. The

plastic mounting strip can be pushed close into the 90-degree angle to

allow maximum length for both sides of the adapter.

Laser Shield Upgrade

For those

who require spectacles for adequate close vision, using laser protective

eyeware can be a problem. This example shows how a cheap

plastic set of lenses from the $2 shop can be inserted at the back of the

protective eyeware in order to provide corrected vision when using

it. The plastic spectacles are best as the bridge can be drilled for

the bolt - metal-framed spectacles would require a small bracket to be

made up. The temple pieces are removed by undoing the screws, but they are

very tiny and it might be just as easy to cut through the plastic.

The only difficult part of the construction is drilling the actual shield

- the plastic needs to be well supported immediately behind the drill

point in order avoid strain on the shield while drilling and to minimize

any risk of cracking it. The lens frame is flexible enough to

be bent to the shape of the eyeware and the screw will hold it into shape,

but very gentle heat can be used to make it conform slightly better.

Clean the lens well before installing to avoid having to remove it later.

For those

who require spectacles for adequate close vision, using laser protective

eyeware can be a problem. This example shows how a cheap

plastic set of lenses from the $2 shop can be inserted at the back of the

protective eyeware in order to provide corrected vision when using

it. The plastic spectacles are best as the bridge can be drilled for

the bolt - metal-framed spectacles would require a small bracket to be

made up. The temple pieces are removed by undoing the screws, but they are

very tiny and it might be just as easy to cut through the plastic.

The only difficult part of the construction is drilling the actual shield

- the plastic needs to be well supported immediately behind the drill

point in order avoid strain on the shield while drilling and to minimize

any risk of cracking it. The lens frame is flexible enough to

be bent to the shape of the eyeware and the screw will hold it into shape,

but very gentle heat can be used to make it conform slightly better.

Clean the lens well before installing to avoid having to remove it later.

Threaded

inserts are commonly used with 3D-printed parts. They are heated and

pushed into molded holes in the part to provide a secure holding for

screws which is much less prone to wear and slipping than plain threaded

plastic. The simplest way to both heat and place the insert is

with a soldering iron. The iron can be set to temperature

(about 225º C seems to be suitable for PLA). There are many

tutorials available showing the technique. But there are three

important points about the procedure that are often not mentioned in the

instructions.

Threaded

inserts are commonly used with 3D-printed parts. They are heated and

pushed into molded holes in the part to provide a secure holding for

screws which is much less prone to wear and slipping than plain threaded

plastic. The simplest way to both heat and place the insert is

with a soldering iron. The iron can be set to temperature

(about 225º C seems to be suitable for PLA). There are many

tutorials available showing the technique. But there are three

important points about the procedure that are often not mentioned in the

instructions.

1. A standard soldering iron tip can be used rather than a set of

insertion adapters, but in that case it should be ground down to the

insert diameter. By providing a tip that is the correct diameter

for the insert the insert will be heated thoroughly and evenly.

Turning the tip in a lathe is the best way to achieve this, but a copper

tip can be turned in a drill against a grinding stone if care is taken.

2. A definite shoulder should be left at the correct height along the

soldering iron tip for the insert. If the tip tapers and there is

not a definite shoulder then there is a risk that the insert will bind

with the tip and it will be pulled out of the part as the soldering iron

is withdrawn.

3. The insert should be the type that has a short length of shaft at the

blind end that can be used for alignment. The hole in the printed

part can then be made to the size of this alignment portion. Without

this feature it is very difficult to get the insert properly started in

the hole, and it will often twist off-centre as it is inserted.

On-line sellers often do not realize the importance of this small feature

and do not make it clear whether it exists or not. Always check the

images carefully when purchasing and return the item as faulty if it was

shown in the image but doesn't actually exist.

To assist with aligning the insert and getting it set flush with the

surface of the printed part, a nut can be set into the copper tip at the

shoulder point. This also assists in getting heat conducted into the

insert. This should be removable for those cases where it interferes with

surrounding material.

The correct temperature setting for the iron when inserting is usually

5°C to 10°C above the extruder temperature used for the material.

Note that the insert will distort surrounding material to some

extent. The inserting may not work correctly where the adjacent wall

thickness is not sufficient to absorb the distortion. Infill percentage

and wall thickness will affect the amount of distortion that can be

accommodated in a particular region.

The 4-port USB assembly fr om

a junked ATX motherboard can be mounted into a stand-alone case and

powered from a high-current 5V supply to provide a convenient recharging

station. The pins connected to the USB data lines are cut off short

and a small harness fabricated for connecting the four +5V pins and the

four Ground pins together. The supply connection can be to flying

leads, or if the bench power distribution has standardized DC connectors,

to the appropriate connectors.

om

a junked ATX motherboard can be mounted into a stand-alone case and

powered from a high-current 5V supply to provide a convenient recharging

station. The pins connected to the USB data lines are cut off short

and a small harness fabricated for connecting the four +5V pins and the

four Ground pins together. The supply connection can be to flying

leads, or if the bench power distribution has standardized DC connectors,

to the appropriate connectors.

Stepper motors are configured as 3-, 4-, 5-, 6- or 8-wire. Three and

five wire steppers are designed for unipolar mode. Four wire steppers are

designed for bipolar mode, while six and eight wire steppers can be either

unipolar or bipolar.

Stepper motors are configured as 3-, 4-, 5-, 6- or 8-wire. Three and

five wire steppers are designed for unipolar mode. Four wire steppers are

designed for bipolar mode, while six and eight wire steppers can be either

unipolar or bipolar.

Unipolar is simpler to drive because a simple switching circuit can

change the polarity of the magnetic field by switching between the two

halves of the coils. For this reason it is very commonly used in small

consumer items, such as toys and small printers. Bipolar requires a

more complex driving circuit but creates better performance,especially if

microstepping is used, because the whole coil is energised when the

current direction is reversed.

Six wire and eight wire steppers are particularly useful because they

can be configured as either unipolar or bipolar. But many 5-wire

steppers can also be configured for either mode. This is because they are

actually constructed as 6-wire steppers with the centre taps connected

together at the wiring attachment point on a small PCB mounted externally

on the motor. If this is the arrangement, then cutting the trace

that connects the centre taps of the two coils means that the 5-wire

(unipolar) stepper is converted to 4-wire (bipolar).

In the first example the trace has been broken at the end of the PCB. The

stepper would be driven with a bipolar driver using orange/red and

brown/black - yellow is not used. The break has been scraped and tinned so

it can be easily bridged with a blob of solder if required for use with a

unipolar driver.

The popular 5V unipolar motor 28BYJ-48 can be converted using this

technique if the cover over the termination block is removed.

In the second example the arrow shows the place where the trace would be

broken to separate the centre taps of the two coils. In both examples

6 wires could be soldered to the PCB so that the selection between unipolar

and bipolar could be done at the other end of the wiring harness.

Header

pins can be difficult to remove because each pin needs to be completely

desoldered. A heated plate or a heat gun will affect other components and

that may not be acceptable. However, it is possible to remove the

pins one by one if the plastic strip holding the pins is removed

first. Usually it can be lifted up and pulled of by first levering

the bottom edge with a sharp blade. If it is reluctant to move, a small

amount of heat will soften it very quickly. For long headers it may

be necessary to slice the plastic strip into several smaller

lengths. Once the plastic strip is removed the pins can be

unsoldered one by one and the holes cleaned out with a solder sucker

and/or wicking braid. In this example a straight header on the upper

surface had to be replaced with an angled header on the bottom surface in

order for the module to fit its case.

Header

pins can be difficult to remove because each pin needs to be completely

desoldered. A heated plate or a heat gun will affect other components and

that may not be acceptable. However, it is possible to remove the

pins one by one if the plastic strip holding the pins is removed

first. Usually it can be lifted up and pulled of by first levering

the bottom edge with a sharp blade. If it is reluctant to move, a small

amount of heat will soften it very quickly. For long headers it may

be necessary to slice the plastic strip into several smaller

lengths. Once the plastic strip is removed the pins can be

unsoldered one by one and the holes cleaned out with a solder sucker

and/or wicking braid. In this example a straight header on the upper

surface had to be replaced with an angled header on the bottom surface in

order for the module to fit its case.

The same technique can be used for double-row headers, but in that case

heating will almost certainly be required to soften the plastic before it

can be removed.

Cheap import boards are often supplied with adjacent multi-pin components

misaligned. This is likely due to automatic placement and soldering

without using an alignment jig. In most cases this is not a problem, but

when the components are part of a module that needs to fit a case cutout,

or when some form of display is involved, the problem needs to be fixed.

If the modules can be aligned with a spring clamp of some form then it is

possible to heat the rear of the PCB with a heat gun to soften the solder

just enough to enable the modules to be move into alignment under the

pressure of the clamp. The images show two 4-digit 7-segment LED displays

clamped and then aligned.

Cheap import boards are often supplied with adjacent multi-pin components

misaligned. This is likely due to automatic placement and soldering

without using an alignment jig. In most cases this is not a problem, but

when the components are part of a module that needs to fit a case cutout,

or when some form of display is involved, the problem needs to be fixed.

If the modules can be aligned with a spring clamp of some form then it is

possible to heat the rear of the PCB with a heat gun to soften the solder

just enough to enable the modules to be move into alignment under the

pressure of the clamp. The images show two 4-digit 7-segment LED displays

clamped and then aligned.

The difficult part is judging the amount of heat to apply - some flux on

the solder joints will provide a guide, as it will bubble as the solder

melts.

The second image shows the before-and-after alignments.

Creating an image for CAD

alignment

A

common task when using CAD to design enclosures for small projects is to map

the cutouts for a faceplate to the position of components such as switches

and LEDs already mounted on the PCB. To do this a photo of the PCB can

be used, but getting it exactly square to the camera can be difficult.

A solution is to scan it with a flatbed scanner, rather than photograph

it. Scanners are specifically designed to eliminate the distortion

usually associated with a camera lens at close range. The item can be

mounted on the scanner, with a small support if required, so it is exactly

square to the face. It would usually be scanned with the lid

raised. Note that an image manipulation program that allows precise

rotational alignment is useful if the item can't be aligned on the scanner

exactly - Paint.Net has an excellent add-in effect "Rotation Bilinear" that

can be used in conjunction with the rectangular selection tool to rotate the

image to perfect alignment. Other graphics applications likely have a

similar tool. The image can be loaded in the CAD application and

scaled using the largest and most identifiable features - usually the

perimeter of the PCB. Note that there may be one distortion

effect from the scanner, although it is easily allowed for: the light source

may not be exactly aligned with the sensor, so shadows of raised features

are not perfectly aligned with the top face of the feature. The

attached image shows how the shafts of the switches appear displaced towards

the bottom of the image by their shadow. The effect is easily allowed

for by using features that are not casting shadows. The example also shows

how cross-reference calculations between constraints can be used to align

components laid out in a pattern using the largest feature of the pattern.

In this case the distance between the components at the end of each row or

column is set and named. Then the intermediate distances are calculated as a

fraction of that distance (one of these must be reference only). The result

is that the component positions are automatically equally distributed along

the total length.

A

common task when using CAD to design enclosures for small projects is to map

the cutouts for a faceplate to the position of components such as switches

and LEDs already mounted on the PCB. To do this a photo of the PCB can

be used, but getting it exactly square to the camera can be difficult.

A solution is to scan it with a flatbed scanner, rather than photograph

it. Scanners are specifically designed to eliminate the distortion

usually associated with a camera lens at close range. The item can be

mounted on the scanner, with a small support if required, so it is exactly

square to the face. It would usually be scanned with the lid

raised. Note that an image manipulation program that allows precise

rotational alignment is useful if the item can't be aligned on the scanner

exactly - Paint.Net has an excellent add-in effect "Rotation Bilinear" that

can be used in conjunction with the rectangular selection tool to rotate the

image to perfect alignment. Other graphics applications likely have a

similar tool. The image can be loaded in the CAD application and

scaled using the largest and most identifiable features - usually the

perimeter of the PCB. Note that there may be one distortion

effect from the scanner, although it is easily allowed for: the light source

may not be exactly aligned with the sensor, so shadows of raised features

are not perfectly aligned with the top face of the feature. The

attached image shows how the shafts of the switches appear displaced towards

the bottom of the image by their shadow. The effect is easily allowed

for by using features that are not casting shadows. The example also shows

how cross-reference calculations between constraints can be used to align

components laid out in a pattern using the largest feature of the pattern.

In this case the distance between the components at the end of each row or

column is set and named. Then the intermediate distances are calculated as a

fraction of that distance (one of these must be reference only). The result

is that the component positions are automatically equally distributed along

the total length.

90-Degree Female

Headers

90-degree female headers don't actually exist, but it is easy to make

your own from a standard female header and a small section of

stripboard. This style of header can be useful where the required

height for a standard header is not available and it is not convenient to

either remove the pins and solder directly to the PCB, or replace the pins

with a 90-degree version.

Note that standard female headers have a significant excess length. It is

quite possible to carve away a few mm of the shroud of the header in order

to reduce the height required. If even more room is required the

male pins can be shortened slightly.

The example shows how to replace the jumpers used for setting for the

CW/CCW rotation of a DC motor driver with a 90-degree header wired to a

SPDT switch.

Zero-offset

risers

There

are some cases where a shield that is normally inserted into a female

header strip on top of the MCU needs to be configured so that there is

zero offset between the base of the shield and the top of the headers on

the MCU in order to minimize the total height of the completed assembly.

The joystick/button shield on the UNO pictured here is an example.

At the same time, this shield will always be the topmost in any

stack, so there is no need for the long-tail female header usually used

for stackable shields. The alternative is to use simple pin headers,

but these are designed to be soldered from the top surface, with the

plastic spacer providing separation on the underside. This

results in a gap when the shield is inserted into the headers.

There

are some cases where a shield that is normally inserted into a female

header strip on top of the MCU needs to be configured so that there is

zero offset between the base of the shield and the top of the headers on

the MCU in order to minimize the total height of the completed assembly.

The joystick/button shield on the UNO pictured here is an example.

At the same time, this shield will always be the topmost in any

stack, so there is no need for the long-tail female header usually used

for stackable shields. The alternative is to use simple pin headers,

but these are designed to be soldered from the top surface, with the

plastic spacer providing separation on the underside. This

results in a gap when the shield is inserted into the headers.

The pins can be soldered in from the underside, but the protruding part

is then too short for good connection to the headers, and in any case the

solder joints create an unwanted gap.

The solution is to use the pins without the spacer and solder the pins

from the top The spacer is needed to correctly align the pins

while soldering, but once the pins are soldered into place the plastic

spacer is no longer needed. If it is removed after soldering then

the shield will sit down firmly on the headers of the MCU with no

additional gap. The image shows a joystick/button shield sitting

flush onto a UNO using this technique.

The important point is to ensure that all soldering is complete and

checked before removing the spacer! However it is also important to

get the correct positioning for the spacer before soldering it into place

on the underside - this ensures that the correct length of pin is

available for inserting into the female header. If the spacer is

left at its default position then, after removing it, there is too much

length to the pin and the shield will not sit flush with the

header. The image shows that the correct position for the

spacer is slightly more to the centre of the pins than the default - the

height of the pins above the PCB should be almost the same as the original

height of the pin above the spacer.

The spacer can be pushed up and down the pins to get the correct pin

height before soldering by inserting the whole row into a scrap of

stripboard and pressing against a solid surface. The spacer can be

easily removed when soldering is complete by gently heating with a heat

gun.

An alternative approach is to remove each pin from the strip and insert

it into place with the shield on top of the MCU, using the female header

of the MCU to position it correctly. This works, but it is difficult

to get right and requires much more time and trouble than using the spacer

for alignment and removing it afterwards. However soldering the pins from

the top while the shield is inserted in the MCU is a useful technique if

changes need to be made to individual pins after the strip is inserted.

Storage box for

crimper jaws

Terminal crimping tools are available in a multi-purpose format, where

the jaws are replaceable, being selected to suit the particular terminal

type to be crimped. Keeping track of the multiple jaws can be

difficult, especially when it comes to finding the matching second of a

pair. The fixture shown here simplifies that storage. It is a

rectangular block with slots that accommodate each pair of jaws, and locks

them in place with a skewer inserted through holes running across the

block.

Freecad Design

File

STL File

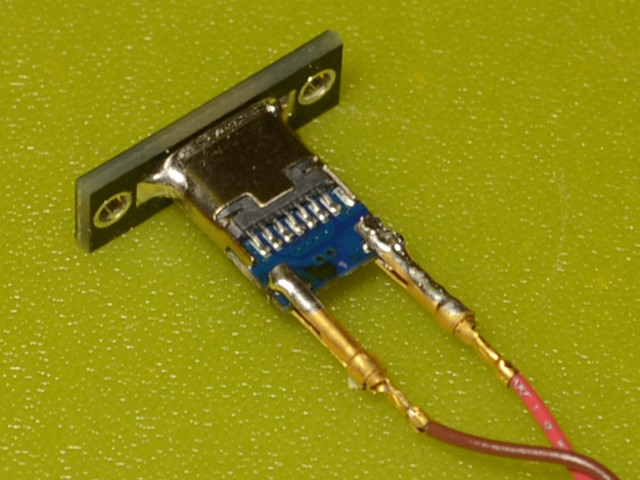

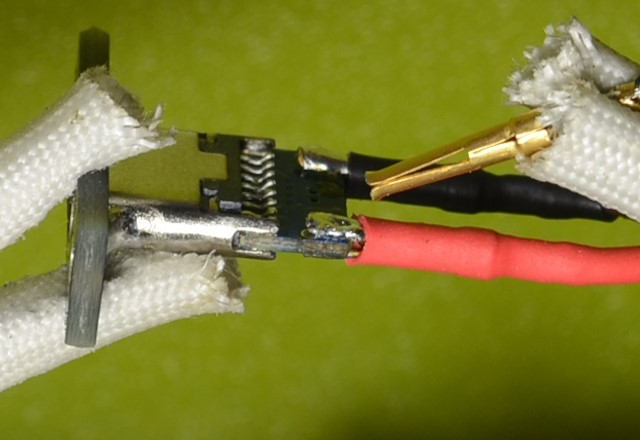

There are some modules, such as this type-C USB port, that are designed

to be soldered directly to a surface connector, like a SMD component. If

the configuration requires a wire to be attached instead, then it can be

difficult to make a connection that is not prone to flexing and

breakage. The image shows how a bifurcated socket insert can be

soldered to both sides of an edge connector on a PCB to provide a very

secure soldered joint.

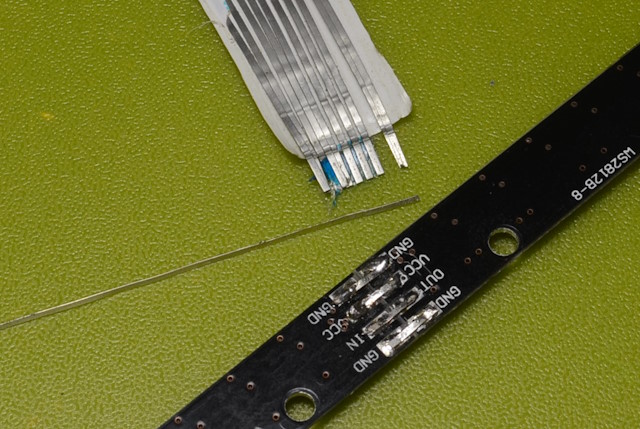

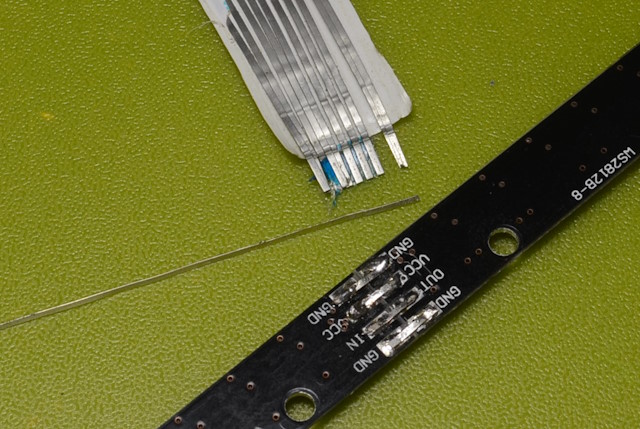

Solderable Metallic

Strips

The metallic strips recovered from older-style flat ribbon cable

make very good connectors for certain types of solder connections.

They tin very easily, are flexible in one direction while being very stiff

in the other, are easy to handle while soldering and can be easily trimmed

to length with small snips. They are shown here used as

interconnects for LED modules. They are recovered by stripping back the

outer covering from the ribbon cable and then peeling the strips away from

the remaining substrate. If necessary they can be cleaned by pulling

through between a razor blade and a flat surface. They are useful in cases

where lengths are too short to be manageable with multi-strand wire, and

where single strand that is thick enough to be handled is too stiff.

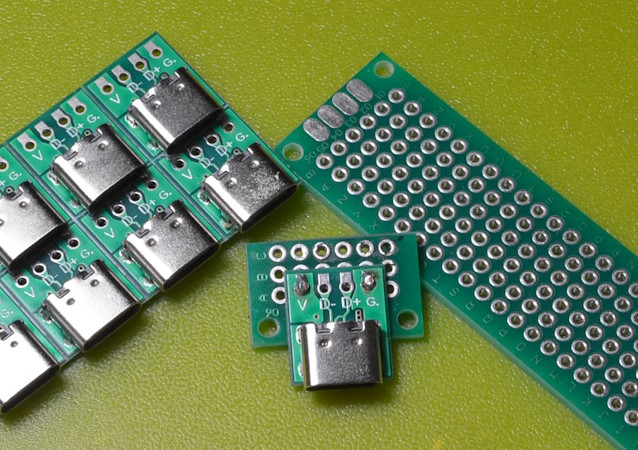

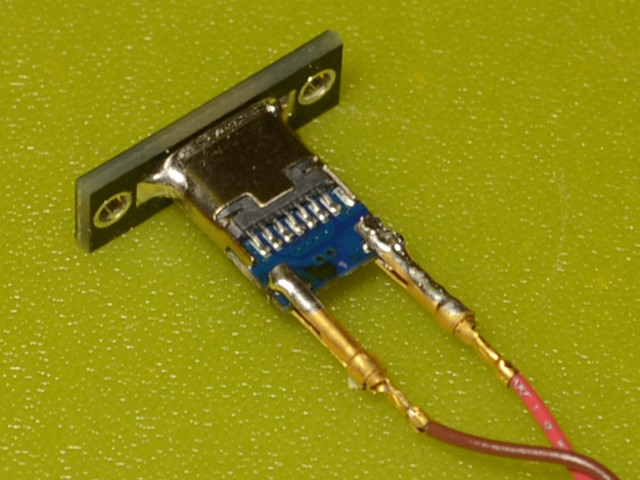

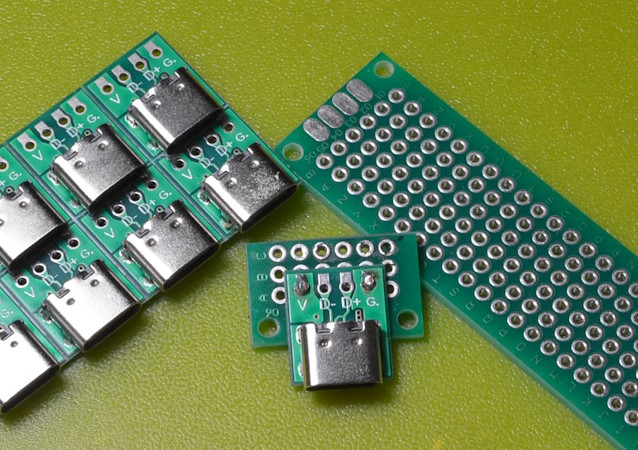

USB Type C Socket Mounting

There

are USB Type C socket modules available that are designed for pins or

soldered connections, but have no mounting points. If they aren't

pinned or soldered direct to a custom PCB, then they can be soldered to one

end of a common style of prototyping board. The type with a 4x0.1"

edge connector has two mounting holes at each end with space between that

exactly fits the width of the socket module. The result is a USB socket that

can be mounted very firmly in the case.

There

are USB Type C socket modules available that are designed for pins or

soldered connections, but have no mounting points. If they aren't

pinned or soldered direct to a custom PCB, then they can be soldered to one

end of a common style of prototyping board. The type with a 4x0.1"

edge connector has two mounting holes at each end with space between that

exactly fits the width of the socket module. The result is a USB socket that

can be mounted very firmly in the case.

This page last updated 31st October 2024

Note that

applying solder to the end of the wire in order to create a solid pin is

not recommended. The contact point with the connector is small and the

solder is liable to deform, especially if the connection is heated, and as

a result the wire loosens in the connector. Also, any bending or vibrating

force is concentrated at the point where the solder finishes, creating a

potential weak point. Ferrules overcome this problem.

Note that

applying solder to the end of the wire in order to create a solid pin is

not recommended. The contact point with the connector is small and the

solder is liable to deform, especially if the connection is heated, and as

a result the wire loosens in the connector. Also, any bending or vibrating

force is concentrated at the point where the solder finishes, creating a

potential weak point. Ferrules overcome this problem.

The

economy versions of these machines come with a controller that supports

height sensing, but no sensor. The purpose of the sensor is to allow

the operator to define the zero level for the work surface. This can

be done by eye and feel, but a simple sensor that detects the circuit

between the tip of the milling bit and the sensor surface simplifies the

procedure considerably.

The

economy versions of these machines come with a controller that supports

height sensing, but no sensor. The purpose of the sensor is to allow

the operator to define the zero level for the work surface. This can

be done by eye and feel, but a simple sensor that detects the circuit

between the tip of the milling bit and the sensor surface simplifies the

procedure considerably.

It is

possible to make up IDC cables without the need for a special clamping

tool. This jig is used to clamp the ribbon cable in the connector,

with both the cable and connector located in the jig so that the whole

assembly can be placed in a vice and clamped. The crosswise groove

accommodates the head of the connector, while the lengthwise groove

accommodates the cable. There are four inserts set into the jig so

that a clamp for the cable can be used, but this is often not

necessary. With the connector pushed into its slot, the cable laid

through the connector in the groove, and the cable clamp screwed down (if

required), the whole assembly is then positioned in the vice while being

held by the cable, and the vice tightened down. The completed unit

can be removed from the jig by pushing from the hole in the bottom.

The cable is then folded back over the header and the retaining bar pushed

on (this might also require pressure from the vice, at it is a very tight

fit).

It is

possible to make up IDC cables without the need for a special clamping

tool. This jig is used to clamp the ribbon cable in the connector,

with both the cable and connector located in the jig so that the whole

assembly can be placed in a vice and clamped. The crosswise groove

accommodates the head of the connector, while the lengthwise groove

accommodates the cable. There are four inserts set into the jig so

that a clamp for the cable can be used, but this is often not

necessary. With the connector pushed into its slot, the cable laid

through the connector in the groove, and the cable clamp screwed down (if

required), the whole assembly is then positioned in the vice while being

held by the cable, and the vice tightened down. The completed unit

can be removed from the jig by pushing from the hole in the bottom.

The cable is then folded back over the header and the retaining bar pushed

on (this might also require pressure from the vice, at it is a very tight

fit).

For those

who require spectacles for adequate close vision, using

For those

who require spectacles for adequate close vision, using  Threaded

inserts are commonly used with 3D-printed parts. They are heated and

pushed into molded holes in the part to provide a secure holding for

screws which is much less prone to wear and slipping than plain threaded

plastic. The simplest way to both heat and place the insert is

with a soldering iron. The iron can be set to temperature

(about 225º C seems to be suitable for PLA). There are many

tutorials available showing the technique. But there are three

important points about the procedure that are often not mentioned in the

instructions.

Threaded

inserts are commonly used with 3D-printed parts. They are heated and

pushed into molded holes in the part to provide a secure holding for

screws which is much less prone to wear and slipping than plain threaded

plastic. The simplest way to both heat and place the insert is

with a soldering iron. The iron can be set to temperature

(about 225º C seems to be suitable for PLA). There are many

tutorials available showing the technique. But there are three

important points about the procedure that are often not mentioned in the

instructions.

om

a junked ATX motherboard can be mounted into a stand-alone case and

powered from a high-current 5V supply to provide a convenient recharging

station. The pins connected to the USB data lines are cut off short

and a small harness fabricated for connecting the four +5V pins and the

four Ground pins together. The supply connection can be to flying

leads, or if the bench power distribution has standardized DC connectors,

to the appropriate connectors.

om

a junked ATX motherboard can be mounted into a stand-alone case and

powered from a high-current 5V supply to provide a convenient recharging

station. The pins connected to the USB data lines are cut off short

and a small harness fabricated for connecting the four +5V pins and the

four Ground pins together. The supply connection can be to flying

leads, or if the bench power distribution has standardized DC connectors,

to the appropriate connectors.

Stepper motors

Stepper motors

A

common task when using CAD to design enclosures for small projects is to map

the cutouts for a faceplate to the position of components such as switches

and LEDs already mounted on the PCB. To do this a photo of the PCB can

be used, but getting it exactly square to the camera can be difficult.

A solution is to scan it with a flatbed scanner, rather than photograph

it. Scanners are specifically designed to eliminate the distortion

usually associated with a camera lens at close range. The item can be

mounted on the scanner, with a small support if required, so it is exactly

square to the face. It would usually be scanned with the lid

raised. Note that an image manipulation program that allows precise

rotational alignment is useful if the item can't be aligned on the scanner

exactly - Paint.Net has an excellent add-in effect "Rotation Bilinear" that

can be used in conjunction with the rectangular selection tool to rotate the

image to perfect alignment. Other graphics applications likely have a

similar tool. The image can be loaded in the CAD application and

scaled using the largest and most identifiable features - usually the

perimeter of the PCB. Note that there may be one distortion

effect from the scanner, although it is easily allowed for: the light source

may not be exactly aligned with the sensor, so shadows of raised features

are not perfectly aligned with the top face of the feature. The

attached image shows how the shafts of the switches appear displaced towards

the bottom of the image by their shadow. The effect is easily allowed

for by using features that are not casting shadows. The example also shows

how cross-reference calculations between constraints can be used to align

components laid out in a pattern using the largest feature of the pattern.

In this case the distance between the components at the end of each row or

column is set and named. Then the intermediate distances are calculated as a

fraction of that distance (one of these must be reference only). The result

is that the component positions are automatically equally distributed along

the total length.

A

common task when using CAD to design enclosures for small projects is to map

the cutouts for a faceplate to the position of components such as switches

and LEDs already mounted on the PCB. To do this a photo of the PCB can

be used, but getting it exactly square to the camera can be difficult.

A solution is to scan it with a flatbed scanner, rather than photograph

it. Scanners are specifically designed to eliminate the distortion

usually associated with a camera lens at close range. The item can be

mounted on the scanner, with a small support if required, so it is exactly

square to the face. It would usually be scanned with the lid

raised. Note that an image manipulation program that allows precise

rotational alignment is useful if the item can't be aligned on the scanner

exactly - Paint.Net has an excellent add-in effect "Rotation Bilinear" that

can be used in conjunction with the rectangular selection tool to rotate the

image to perfect alignment. Other graphics applications likely have a

similar tool. The image can be loaded in the CAD application and

scaled using the largest and most identifiable features - usually the

perimeter of the PCB. Note that there may be one distortion

effect from the scanner, although it is easily allowed for: the light source

may not be exactly aligned with the sensor, so shadows of raised features

are not perfectly aligned with the top face of the feature. The

attached image shows how the shafts of the switches appear displaced towards

the bottom of the image by their shadow. The effect is easily allowed

for by using features that are not casting shadows. The example also shows

how cross-reference calculations between constraints can be used to align

components laid out in a pattern using the largest feature of the pattern.

In this case the distance between the components at the end of each row or

column is set and named. Then the intermediate distances are calculated as a

fraction of that distance (one of these must be reference only). The result

is that the component positions are automatically equally distributed along

the total length.

There

are some cases where a shield that is normally inserted into a female

header strip on top of the MCU needs to be configured so that there is

zero offset between the base of the shield and the top of the headers on

the MCU in order to minimize the total height of the completed assembly.

The joystick/button shield on the UNO pictured here is an example.

At the same time, this shield will always be the topmost in any

stack, so there is no need for the long-tail female header usually used

for stackable shields. The alternative is to use simple pin headers,

but these are designed to be soldered from the top surface, with the

plastic spacer providing separation on the underside. This

results in a gap when the shield is inserted into the headers.

There

are some cases where a shield that is normally inserted into a female

header strip on top of the MCU needs to be configured so that there is

zero offset between the base of the shield and the top of the headers on

the MCU in order to minimize the total height of the completed assembly.

The joystick/button shield on the UNO pictured here is an example.

At the same time, this shield will always be the topmost in any

stack, so there is no need for the long-tail female header usually used

for stackable shields. The alternative is to use simple pin headers,

but these are designed to be soldered from the top surface, with the

plastic spacer providing separation on the underside. This

results in a gap when the shield is inserted into the headers.

There

are USB Type C socket modules available that are designed for pins or

soldered connections, but have no mounting points. If they aren't

pinned or soldered direct to a custom PCB, then they can be soldered to one

end of a common style of prototyping board. The type with a 4x0.1"

edge connector has two mounting holes at each end with space between that

exactly fits the width of the socket module. The result is a USB socket that

can be mounted very firmly in the case.

There

are USB Type C socket modules available that are designed for pins or

soldered connections, but have no mounting points. If they aren't

pinned or soldered direct to a custom PCB, then they can be soldered to one

end of a common style of prototyping board. The type with a 4x0.1"

edge connector has two mounting holes at each end with space between that

exactly fits the width of the socket module. The result is a USB socket that

can be mounted very firmly in the case.