Timer Project

The objective of the project was to create a timer module that could trigger

a relay multiple times at a predetermined interval. The timer would be

used for interval-timer photography, such as recording a 3D print to play

back in super fast motion. Although this project uses the timer to operate a

relay that is connected to a camera shutter release, it could instead

trigger a LED to signal an optical device, or trigger a shutter

directly. Currently the relay is external to the unit, but there is

space in the case for including an internal relay.

PARTS.

U1 Arduino Pro Mini. I chose the Pro over the Nano

because I do not expect to be re-programming it and the USB interface

could not be justified. The programming pins are accessible if needed.

L1 128x64 OLED display with I2C interface to display the settings and the

progress. Header pins and sockets to suit. This model OLED

uses a different colour for the top few rows, and the code takes advantage

of this.

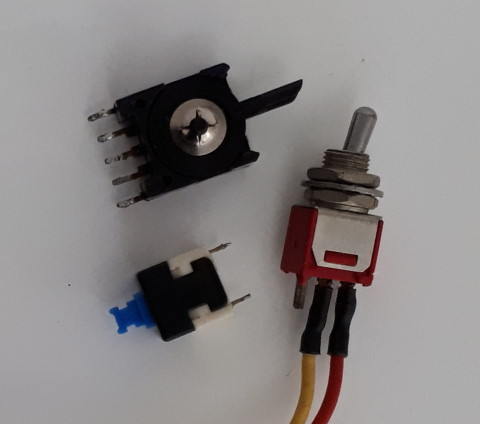

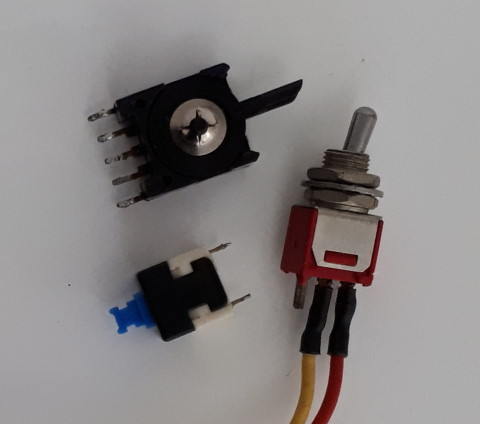

SW1 Momentary SPDT switch for up/down control. Salvaged from an old CD

drive. Two single pole momentary switches could also be used, but

the 'rocker' style of this switch is very easy to use.

SW2 Momentary SPST switch for reset. Salvaged from somewhere.

SW3 SPST On/Off switch. Salvaged from the PCB of some old piece of gear.

D1 LED and matched R1 resistor (eg 220ohm).

Hookup wire and prototype board (see below).

Q1 Small NPN power transistor. (Eg 2N2222) and resistor as required for

the load to be driven (eg 1k)

B1 9v Battery with clip and leads.

3D printed case.

The

switches can be anything suitable, but the height needs to be considered if

they are all mounted at the same level on the prototype board. The

'rocker' style switch used for the up/down adjustment has five pins but only

three connections - each pair of outer pins is the same side of the

switch.

The

switches can be anything suitable, but the height needs to be considered if

they are all mounted at the same level on the prototype board. The

'rocker' style switch used for the up/down adjustment has five pins but only

three connections - each pair of outer pins is the same side of the

switch.

The OLED display is a common, easily available item. For this

project I mounted it using the header pins inserted into a matching header

socket mounted to the breadboard. These displays are also available with

an ISP interface - either would work for this project, but the extra speed

of ISP is not required. The display sits below the cutout in the lid

and is supported by the header pins and a small packing piece under the

substrate. I avoided a more solid mount because of the risk of fracturing

the delicate glass face plate.

The prototype board I used is marked 2-110 and is similar to this.

It is actually designed for the Pro module to straddle the centre row, but

as I am only using a few pins for the module it was easier to put it at the

bottom of the board and leave space for the other components at the top.

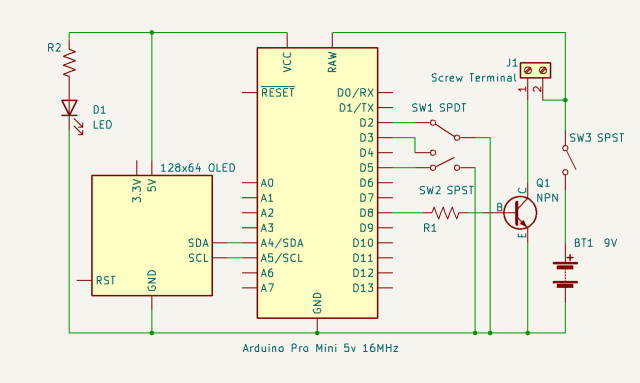

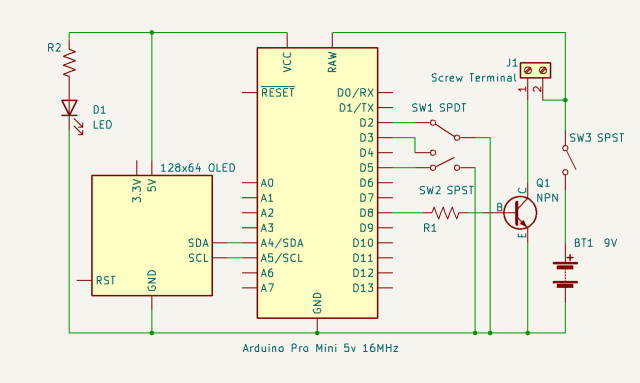

THE CIRCUIT

The 9v battery power is provided via the on/off

switch to VRaw of the Pro. Vcc from the Pro is wired to the

OLED. The grounds of both devices are tied to battery ground.

The up/down switch for setting the timer period is connected to data pins 2

and 3 (active low) and the start/stop button is connected to data pin 5

(active low). Output to the transistor and the relay is at data

pin 8 There is no particular reason for choosing these pins -

any data pins would work as well. The OLED is driven from the standard

UNO/Pro SDA and SCL pins.

The 9v battery power is provided via the on/off

switch to VRaw of the Pro. Vcc from the Pro is wired to the

OLED. The grounds of both devices are tied to battery ground.

The up/down switch for setting the timer period is connected to data pins 2

and 3 (active low) and the start/stop button is connected to data pin 5

(active low). Output to the transistor and the relay is at data

pin 8 There is no particular reason for choosing these pins -

any data pins would work as well. The OLED is driven from the standard

UNO/Pro SDA and SCL pins.

ASSEMBLY

The

Pro has header pins soldered on two edges and for the programming pins, but

not across the fourth side as this would make things too crowded on the

prototype board. I soldered leads to the prototype boards before

soldering the Pro on, as with this particular board the traces to the header

pins are only available between the header rows. Although this makes things

a bit tricky it saves a lot of board space and is much easier than trying to

solder on the trace side of the board. I also soldered some leads to

some of the unused pin traces in case I wanted to add new features later

on. The hookup wire came from an old parallel printer cable.

This wire is easily tinned and soldered, the covering is very heat

resistant, it is quite flexible, and the multitude of colours means that the

wire can indicate the function of the connection, reducing the risk of

mistakes.

The

Pro has header pins soldered on two edges and for the programming pins, but

not across the fourth side as this would make things too crowded on the

prototype board. I soldered leads to the prototype boards before

soldering the Pro on, as with this particular board the traces to the header

pins are only available between the header rows. Although this makes things

a bit tricky it saves a lot of board space and is much easier than trying to

solder on the trace side of the board. I also soldered some leads to

some of the unused pin traces in case I wanted to add new features later

on. The hookup wire came from an old parallel printer cable.

This wire is easily tinned and soldered, the covering is very heat

resistant, it is quite flexible, and the multitude of colours means that the

wire can indicate the function of the connection, reducing the risk of

mistakes.

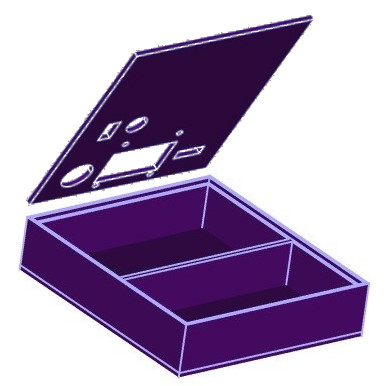

THE CASE

The case is a simple two-part assembly, with a lid that

sits down into the base without any attachment. The lid would be a good

candidate for a magnetic attachment. The base is divided into two

parts - one is a tight fit for the prototyping board and the other is a

large area for the battery. I did not divide this area because I might

want to install the relay, which currently swings freely at the end of a

wire, inside the case at some time in the future. Foam spacers can be used

to stop the battery sliding around. The relay lead exits the case

through a hole near the bottom left corner of the prototype board.

The case is a simple two-part assembly, with a lid that

sits down into the base without any attachment. The lid would be a good

candidate for a magnetic attachment. The base is divided into two

parts - one is a tight fit for the prototyping board and the other is a

large area for the battery. I did not divide this area because I might

want to install the relay, which currently swings freely at the end of a

wire, inside the case at some time in the future. Foam spacers can be used

to stop the battery sliding around. The relay lead exits the case

through a hole near the bottom left corner of the prototype board.

I printed knobs for the reset and power switches so

they would match the case, and added a small surround for the LED to make

it look a bit neater. I filled the mounting holes for the OLED with plugs,

after deciding that I did not want to screw the device down to the lid.

COMPLETED

The completed unit, with the lid pushed down into the

base. When the unit is is turned on the interval between ticks can be

set using the momentary rocker switch - right to increase and left to

decrease. Timing is started and stopped with the large momentary

switch to the left of the display. If this is pressed when the timer is

running then the display is inverted to show that timing is paused.

The current interval and the number of ticks are displayed. If

start/stop is pressed again the count is cleared to 0 and timing starts.

The completed unit, with the lid pushed down into the

base. When the unit is is turned on the interval between ticks can be

set using the momentary rocker switch - right to increase and left to

decrease. Timing is started and stopped with the large momentary

switch to the left of the display. If this is pressed when the timer is

running then the display is inverted to show that timing is paused.

The current interval and the number of ticks are displayed. If

start/stop is pressed again the count is cleared to 0 and timing starts.

CODE

The timer uses a timer library with interrupts. There

are several timer libraries available for the Arduino, so substituting a

different one would not be a problem. The interrupt-handling routine

breaks most of the rules for using interrupts, but as the time interval is

completely controlled by the code it doesn't create a problem. The timing

interval can be set from one second to 9999 seconds. To make this

possible with a simple user interface acceleration is used - each time the

interval is increased or decreased the rate of change is raised by a

factor of 1.2. So holding the switch in one direction or the other

gradually increases the rate at which the interval increases or

decreases. The full range of 1 to 9999 takes about 15s. If the

switch goes back to neutral the step is reset to 1, so that at any point

the interval can be set to an accuracy of 1s by briefly flicking the

switch.

Code is included to save the currently selected

interval to EEProm so that it can be retrieved at startup and set as the

default.

/**************************************************************************

Timer using OLED based on SSD1306 drivers

This sketch uses a 128x64 pixel display using I2C to communicate.

4 pins are required to interface.

Vcc --> +5v

Gnd --> Gnd

SCL --> A5

SDA --> A4

2-colour OLED has 16 lines of yellow and 48 lines of blue (pixel

lines are numbered 0 to 63).

Oled library is at:

https://adafruit.github.io/Adafruit_SSD1306/html/class_adafruit___s_s_d1306.html

Timer library is at:

http://www.doctormonk.com/2012/01/arduino-timer-library.html

**************************************************************************/

#include <SPI.h>

#include <Wire.h>

#include <Adafruit_GFX.h>

#include <Adafruit_SSD1306.h>

#include <Timer.h>

#include <EEPROM.h>

#define SCREEN_WIDTH 128 // OLED display width, in pixels

#define SCREEN_HEIGHT 64 // OLED display height, in pixels

// Declaration for an SSD1306 display connected to I2C (SDA, SCL pins)

#define OLED_RESET 4 // Reset pin # (or -1 if

sharing Arduino reset pin)

Adafruit_SSD1306 display(SCREEN_WIDTH, SCREEN_HEIGHT, &Wire,

OLED_RESET);

Timer t; // Create the timer instance.

long period;

int8_t tickEvent;

long count = 0;

String pMessage;

String cMessage;

const int buttonUpPin = 2; // the number of the

button pin for UP

const int buttonDnPin = 3; // the number of the

button pin for DOWN

const int buttonRsPin = 5; // the number of the

button pin for RESET

const int clickPin = 8; // then

number of the button pin for CLICK

int buttonUpState = 0; //

variable for reading the button UP status

int buttonDnState = 0; //

variable for reading the button DOWN status

int buttonRsState = 0; //

variable for reading the button RESET status

float buttonStep = 1.0; // Step

per button press

boolean running = false; // the state

of the timer

void setup() {

//

Serial.begin(9600); //

Needed if debugging the display

// SSD1306_SWITCHCAPVCC = generate display voltage from 3.3V

internally

if (!display.begin(SSD1306_SWITCHCAPVCC, 0x3C)) { // Address 0x3D

for 128x64

// Serial.println(F("SSD1306 allocation

failed")); // Uncomment if the display doesn't start.

for (;;); // Don't proceed, loop forever

}

// Show initial display buffer contents on the screen --

// the library initializes this with an Adafruit splash screen.

//

display.display();

// Don't need it.

// delay(500); // Pause for 2 seconds

// initialize the button and clicker pins:

pinMode(buttonUpPin, INPUT_PULLUP);

pinMode(buttonDnPin, INPUT_PULLUP);

pinMode(buttonRsPin, INPUT_PULLUP);

pinMode(clickPin, OUTPUT);

digitalWrite(clickPin, LOW); // Initialize the click output.

// Get the saved period

period = readLongFromEEPROM(0);

if (period < 1 || period > 9999L) period = 5;

// initialize the timer and show the first screen

tickEvent = t.every(period * 1000, doClick, NULL);

DrawScreen();

}

void loop() {

// read the state of the buttons

buttonUpState = digitalRead(buttonUpPin);

buttonDnState = digitalRead(buttonDnPin);

// If neither button is pressed, reset the button

acceleration

if (!(buttonUpState == LOW || buttonDnState == LOW)) buttonStep =

1.0;

// check if the UP button is pressed. If it is, the button state is

LOW:

if (buttonUpState == LOW) {

// Bump the Period

period = period + long(buttonStep);

// Bump the acceleration

buttonStep *= 1.2;

if (period > 9999L) {

period = 9999L;

}

// Restart the timer

t.stop(tickEvent);

tickEvent = t.every(period * 1000, doClick, NULL);

// Debounce

delay(250);

DrawScreen();

}

// check if the DOWN button is pressed. If it is, the button state

is LOW:

if (buttonDnState == LOW) {

// Debump the Period

period = period - long(buttonStep);

// Bump the acceleration

buttonStep *= 1.2;

if (period < 1L) {

period = 1L;

}

t.stop(tickEvent);

tickEvent = t.every(period * 1000, doClick, NULL);

// Debounce

delay(250);

DrawScreen(); //

}

buttonRsState = digitalRead(buttonRsPin);

// check if the RESET button is pressed. If it is, the button state

is LOW:

if (buttonRsState == LOW) {

// Change the timer state.

display.invertDisplay(running);

running = !running;

if (running) {

count = 0; //

Iniitialize the click counter

writeLongIntoEEPROM(0, period); // Update

the saved period.

}

// Serial.println("Reset");

// Debounce

delay(250);

DrawScreen();

}

if (running) {

t.update();

}

}

void DrawScreen(void) {

display.clearDisplay();

display.setTextSize(2);

display.setTextColor(SSD1306_WHITE);

display.setCursor(7, 0);

display.println(F("PhotoTimer"));

display.setTextSize(2);

display.setCursor(3, 21);

display.println(F("Delay:"));

display.setCursor(75, 21);

display.println(int(period));

display.setCursor(3, 46);

display.println(F("Count:"));

display.setCursor(75, 46);

display.println(int(count));

display.display();

}

void doClick(void *context) {

count += 1;

digitalWrite(clickPin, HIGH);

digitalWrite(LED_BUILTIN, HIGH);

delay(500);

digitalWrite(clickPin, LOW);

digitalWrite(LED_BUILTIN, LOW);

DrawScreen();

}

long readLongFromEEPROM(int address)

{

long number = ((long)EEPROM.read(address) << 24) +

((long)EEPROM.read(address + 1) << 16) +

((long)EEPROM.read(address + 2) << 8) +

(long)EEPROM.read(address

+ 3);

return number;

}

void writeLongIntoEEPROM(int address, long number)

{

EEPROM.write(address, (number >> 24) & 0xFF);

EEPROM.write(address + 1, (number >> 16) & 0xFF);

EEPROM.write(address + 2, (number >> 8) & 0xFF);

EEPROM.write(address + 3, number & 0xFF);

}

This page last update 18 August 2024

The case is a simple two-part assembly, with a lid that

sits down into the base without any attachment. The lid would be a good

candidate for a magnetic attachment. The base is divided into two

parts - one is a tight fit for the prototyping board and the other is a

large area for the battery. I did not divide this area because I might

want to install the relay, which currently swings freely at the end of a

wire, inside the case at some time in the future. Foam spacers can be used

to stop the battery sliding around. The relay lead exits the case

through a hole near the bottom left corner of the prototype board.

The case is a simple two-part assembly, with a lid that

sits down into the base without any attachment. The lid would be a good

candidate for a magnetic attachment. The base is divided into two

parts - one is a tight fit for the prototyping board and the other is a

large area for the battery. I did not divide this area because I might

want to install the relay, which currently swings freely at the end of a

wire, inside the case at some time in the future. Foam spacers can be used

to stop the battery sliding around. The relay lead exits the case

through a hole near the bottom left corner of the prototype board. The

switches can be anything suitable, but the height needs to be considered if

they are all mounted at the same level on the prototype board. The

'rocker' style switch used for the up/down adjustment has five pins but only

three connections - each pair of outer pins is the same side of the

switch.

The

switches can be anything suitable, but the height needs to be considered if

they are all mounted at the same level on the prototype board. The

'rocker' style switch used for the up/down adjustment has five pins but only

three connections - each pair of outer pins is the same side of the

switch.

The 9v battery power is provided via the on/off

switch to VRaw of the Pro. Vcc from the Pro is wired to the

OLED. The grounds of both devices are tied to battery ground.

The up/down switch for setting the timer period is connected to data pins 2

and 3 (active low) and the start/stop button is connected to data pin 5

(active low). Output to the transistor and the relay is at data

pin 8 There is no particular reason for choosing these pins -

any data pins would work as well. The OLED is driven from the standard

UNO/Pro SDA and SCL pins.

The 9v battery power is provided via the on/off

switch to VRaw of the Pro. Vcc from the Pro is wired to the

OLED. The grounds of both devices are tied to battery ground.

The up/down switch for setting the timer period is connected to data pins 2

and 3 (active low) and the start/stop button is connected to data pin 5

(active low). Output to the transistor and the relay is at data

pin 8 There is no particular reason for choosing these pins -

any data pins would work as well. The OLED is driven from the standard

UNO/Pro SDA and SCL pins. The

Pro has header pins soldered on two edges and for the programming pins, but

not across the fourth side as this would make things too crowded on the

prototype board. I soldered leads to the prototype boards before

soldering the Pro on, as with this particular board the traces to the header

pins are only available between the header rows. Although this makes things

a bit tricky it saves a lot of board space and is much easier than trying to

solder on the trace side of the board. I also soldered some leads to

some of the unused pin traces in case I wanted to add new features later

on. The hookup wire came from an old parallel printer cable.

This wire is easily tinned and soldered, the covering is very heat

resistant, it is quite flexible, and the multitude of colours means that the

wire can indicate the function of the connection, reducing the risk of

mistakes.

The

Pro has header pins soldered on two edges and for the programming pins, but

not across the fourth side as this would make things too crowded on the

prototype board. I soldered leads to the prototype boards before

soldering the Pro on, as with this particular board the traces to the header

pins are only available between the header rows. Although this makes things

a bit tricky it saves a lot of board space and is much easier than trying to

solder on the trace side of the board. I also soldered some leads to

some of the unused pin traces in case I wanted to add new features later

on. The hookup wire came from an old parallel printer cable.

This wire is easily tinned and soldered, the covering is very heat

resistant, it is quite flexible, and the multitude of colours means that the

wire can indicate the function of the connection, reducing the risk of

mistakes.  The completed unit, with the lid pushed down into the

base. When the unit is is turned on the interval between ticks can be

set using the momentary rocker switch - right to increase and left to

decrease. Timing is started and stopped with the large momentary

switch to the left of the display. If this is pressed when the timer is

running then the display is inverted to show that timing is paused.

The current interval and the number of ticks are displayed. If

start/stop is pressed again the count is cleared to 0 and timing starts.

The completed unit, with the lid pushed down into the

base. When the unit is is turned on the interval between ticks can be

set using the momentary rocker switch - right to increase and left to

decrease. Timing is started and stopped with the large momentary

switch to the left of the display. If this is pressed when the timer is

running then the display is inverted to show that timing is paused.

The current interval and the number of ticks are displayed. If

start/stop is pressed again the count is cleared to 0 and timing starts.