LED Array Test Box Project

This simple project is a little test box that includes 6 LEDs that can

be safely driven from the GPIO ports of any MCU. The device is

very useful for quick testing of prototypes - a few lines of code can

drive LEDs on any spare pin of the prototype to provide a visual

indication of what it is doing. I tend to set up these indicators

and leave them largely unchanged, and use the serial monitor for detailed

debugging information. It works like a very simple logic

analyzer.

The box has connections for 5v and Gnd, and an input pin for the six

LEDs. The inputs are buffered so that the load on each input is

about 1.6mA each: that is well within the 20mA per-pin maximum of the

Arduino UNO, and also well within 200mA total for all pins.

Parts

DM/SN7407 Hex buffer, or similar (eg, 7417)

6 x LEDs with dropping resistors to suit. This project uses bright

white LEDs with 150Ω resistors. Standard red or green LEDs typically use

220Ω or 330Ω resistors.

Prototype board approx. 4cm x 6cm. Many styles would work.

Headers: 2 x 3-pin, 1 x 6-pin.

3D printed case.

DM/SN7407 Integrated Circuit

The 7407 medium-scale integrated circuit is a hex

buffer/driver with open collector outputs. Hex simply means there

are six separate buffers/drivers within the chip. Open collector

means that the output is a transistor switch - on or off - that switches

the supply from some external source to ground. In this case the

external voltage source is actually the same 5v supply that powers the

chip, but in other applications it could be a supply of up to about

30v. The maximum current for each switched circuit is 40mA - well

within the 20mA typically required for a LED. These chips are easily

recovered from obsolete equipment - they are large enough to solder with a

typical hobby soldering iron, but small enough to fit into a suitable

device case. Note that there are several variations of this chip, such as

'LS' and 'S', and also 5407 which is a lower voltage military version: any

of these variants is suitable for this project.

The 7407 medium-scale integrated circuit is a hex

buffer/driver with open collector outputs. Hex simply means there

are six separate buffers/drivers within the chip. Open collector

means that the output is a transistor switch - on or off - that switches

the supply from some external source to ground. In this case the

external voltage source is actually the same 5v supply that powers the

chip, but in other applications it could be a supply of up to about

30v. The maximum current for each switched circuit is 40mA - well

within the 20mA typically required for a LED. These chips are easily

recovered from obsolete equipment - they are large enough to solder with a

typical hobby soldering iron, but small enough to fit into a suitable

device case. Note that there are several variations of this chip, such as

'LS' and 'S', and also 5407 which is a lower voltage military version: any

of these variants is suitable for this project.

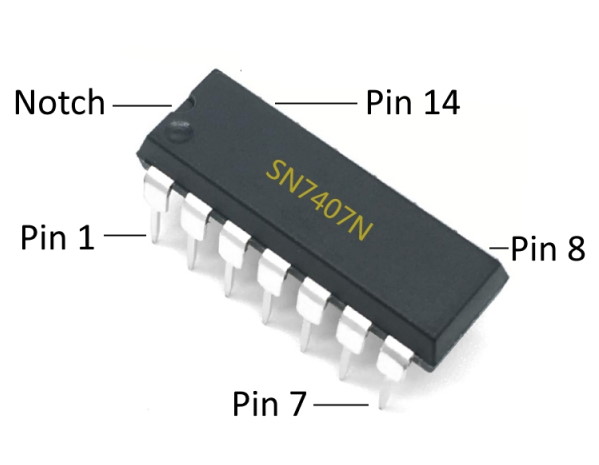

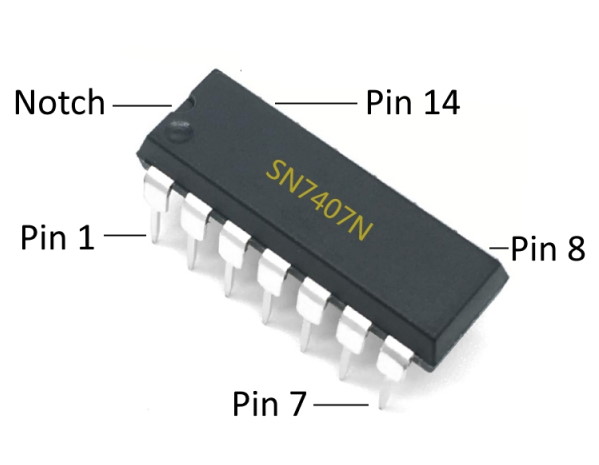

Note that the notch at the end of the chip defines the pin

numbering. With the notch at the left-hand end, looking from above,

pin numbers start at the lower left-hand corner and proceed

anti-clockwise. The lettering is usually aligned with the notch at

the left, but do not rely on it.

THE CIRCUIT

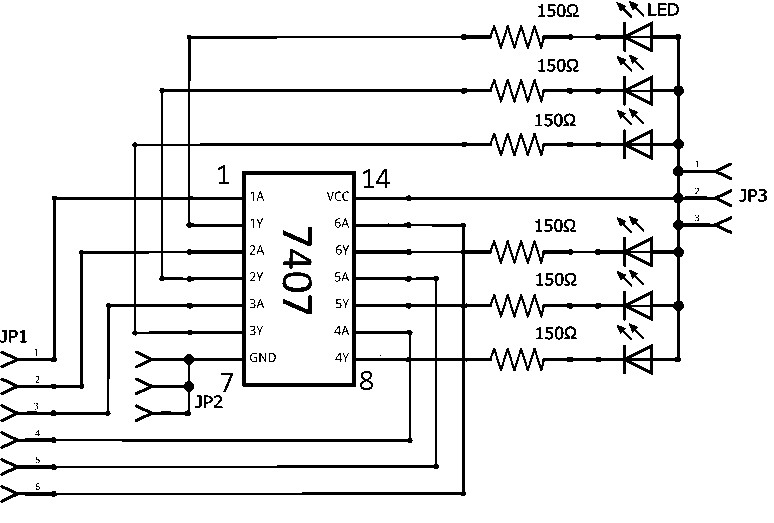

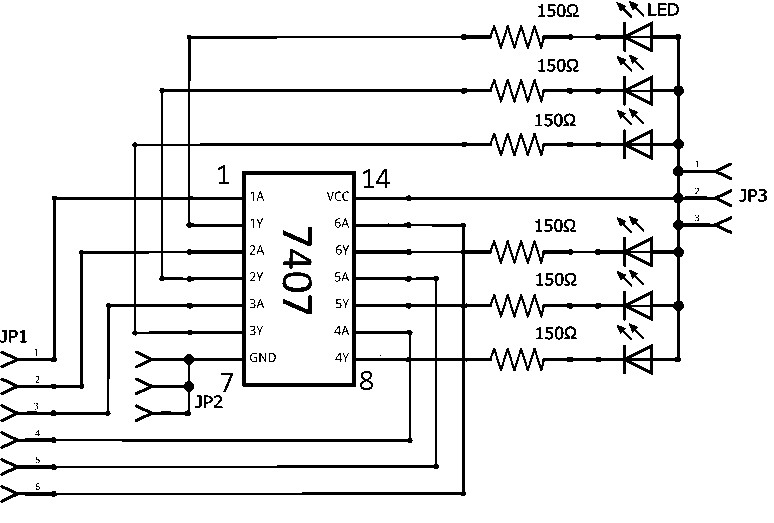

Pins 7 and 14

of the 7407 are connected to the ground and +5v 3-pin headers

respectively. The 6-pin input header JP1 is connected to the input

pins (1A through 6A) of the 7407, while the output pins (1Y through 6Y)

are connected via resistors to the LEDs and then to the LED driver voltage

at JP3. When the logic level at the input of the 7407 is high then

the corresponding transistor switch turns on and connects the LED to

ground through the GND (pin 7, JP2) of the 7407.

Pins 7 and 14

of the 7407 are connected to the ground and +5v 3-pin headers

respectively. The 6-pin input header JP1 is connected to the input

pins (1A through 6A) of the 7407, while the output pins (1Y through 6Y)

are connected via resistors to the LEDs and then to the LED driver voltage

at JP3. When the logic level at the input of the 7407 is high then

the corresponding transistor switch turns on and connects the LED to

ground through the GND (pin 7, JP2) of the 7407.

In this configuration the LED driver voltage is the same as the 7407

supply voltage, that is, 5V at pin 14. The alternative arrangement

is to disconnect JP3 from pin 14, supply 5V separately to pin 14, and

connect the alternate LED supply voltage to JP3. This alternate

supply must be no greater than 30V, and LEDS+resistors, or relays or

whatever other device is used must be capable of handling the higher

voltage. There must be a common ground between each supply, the test

unit and the MCU.

ASSEMBLY

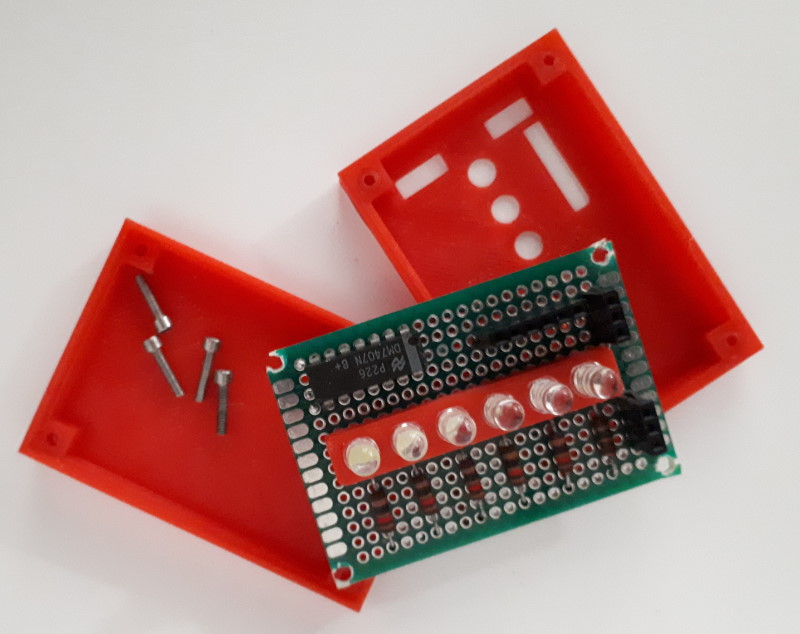

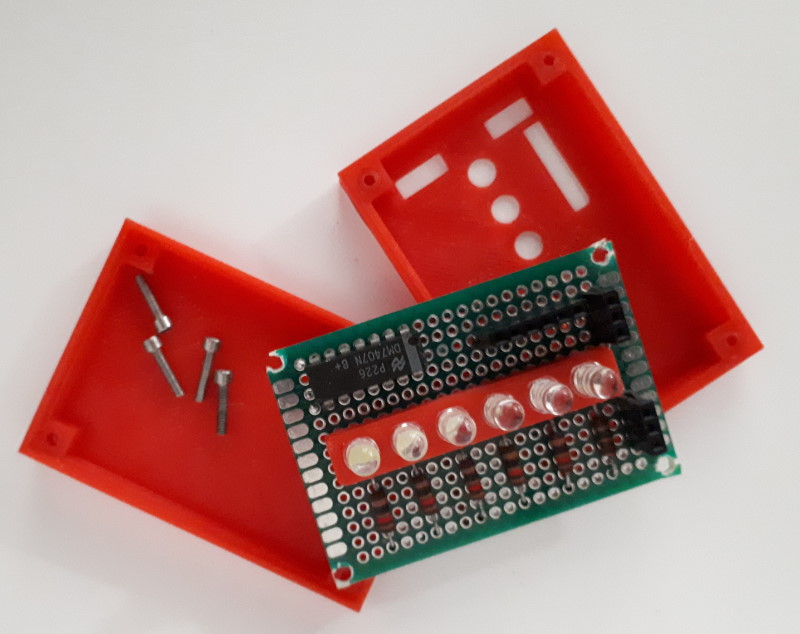

The parts are laid out on the prototyping board in a form that keeps the

wiring as simple as possible. In this example I have placed the LEDs

across the middle, with their resistors running to a buss at the

top. The +5v and Gnd headers are off to one side, and the input

header is aligned below the LEDs. The board can then be wired

point-to-point on the underside. The hookup wire came from an old

parallel printer cable. This wire is easily tinned and soldered, the

covering is very heat resistant, it is quite flexible, and the multitude

of colours means that the wire can indicate the function of the

connection, reducing the risk of mistakes. Note that I printed a standoff

for the row of LEDs - this helped to keep them properly aligned for height

and position.

The case is a simple two-part assembly, with a base

that the prototyping board sits down into, and which then screws through

countersunk holes from the back into standoffs in the lid. The lid

has cutouts for the LEDs and the headers. The screws self-thread into the

holes in the lid - a solution that is adequate for such a small case. The

screws were slightly too big for the holes in the prototyping board: the

corners could be cut away completely because the board is held securely

between the base and the lid.

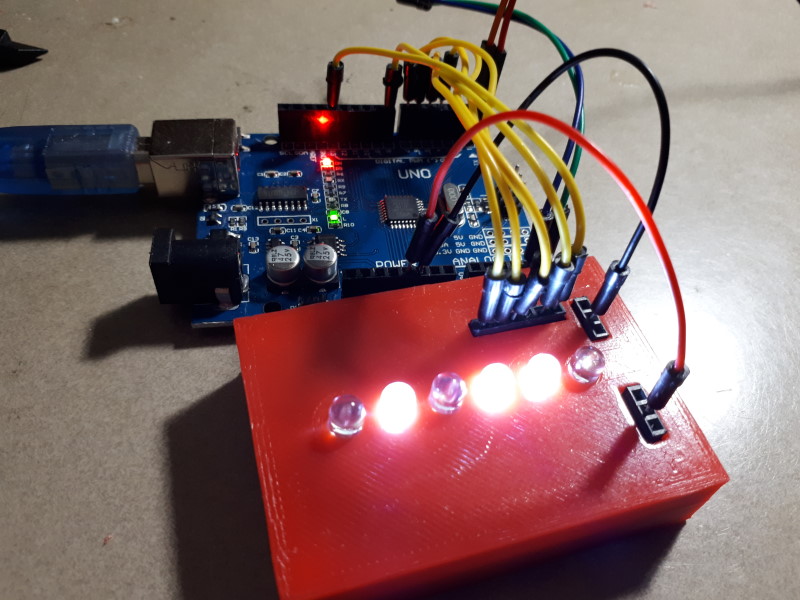

COMPLETED

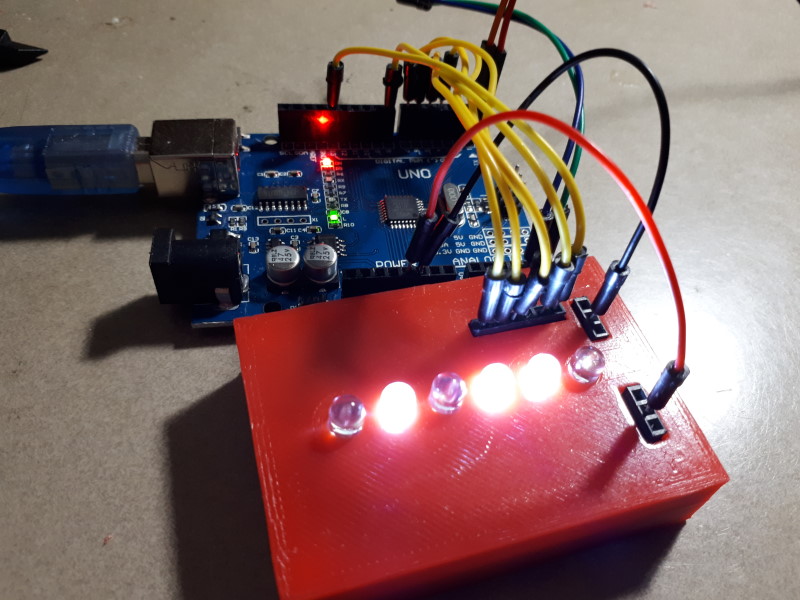

The completed unit, with the lid screwed onto the base and connected to a

UNO. There ar small markings molded into the lid to identify the +5v

and Gnd headers, but it doesn't show in the images. To use the

unit, +5v and Gnd connections are plugged in the respective headers, and

then output pins from the MCU are connected to the input header. When

the output is high the LED is lit. The +5v and Gnd headers

provide a convenient point for taking off connections to other items being

tested.

If the +5v supply does not come from the Arduino then it is critical that

the GND from the test unit is connected to the Gnd on the Arduino.

This site was last updated 6th

August 2024.

This site was last updated 6th

August 2024.

The 7407 medium-scale integrated circuit is a hex

buffer/driver with open collector outputs. Hex simply means there

are six separate buffers/drivers within the chip. Open collector

means that the output is a transistor switch - on or off - that switches

the supply from some external source to ground. In this case the

external voltage source is actually the same 5v supply that powers the

chip, but in other applications it could be a supply of up to about

30v. The maximum current for each switched circuit is 40mA - well

within the 20mA typically required for a LED. These chips are easily

recovered from obsolete equipment - they are large enough to solder with a

typical hobby soldering iron, but small enough to fit into a suitable

device case. Note that there are several variations of this chip, such as

'LS' and 'S', and also 5407 which is a lower voltage military version: any

of these variants is suitable for this project.

The 7407 medium-scale integrated circuit is a hex

buffer/driver with open collector outputs. Hex simply means there

are six separate buffers/drivers within the chip. Open collector

means that the output is a transistor switch - on or off - that switches

the supply from some external source to ground. In this case the

external voltage source is actually the same 5v supply that powers the

chip, but in other applications it could be a supply of up to about

30v. The maximum current for each switched circuit is 40mA - well

within the 20mA typically required for a LED. These chips are easily

recovered from obsolete equipment - they are large enough to solder with a

typical hobby soldering iron, but small enough to fit into a suitable

device case. Note that there are several variations of this chip, such as

'LS' and 'S', and also 5407 which is a lower voltage military version: any

of these variants is suitable for this project.  Pins 7 and 14

of the 7407 are connected to the ground and +5v 3-pin headers

respectively. The 6-pin input header JP1 is connected to the input

pins (1A through 6A) of the 7407, while the output pins (1Y through 6Y)

are connected via resistors to the LEDs and then to the LED driver voltage

at JP3. When the logic level at the input of the 7407 is high then

the corresponding transistor switch turns on and connects the LED to

ground through the GND (pin 7, JP2) of the 7407.

Pins 7 and 14

of the 7407 are connected to the ground and +5v 3-pin headers

respectively. The 6-pin input header JP1 is connected to the input

pins (1A through 6A) of the 7407, while the output pins (1Y through 6Y)

are connected via resistors to the LEDs and then to the LED driver voltage

at JP3. When the logic level at the input of the 7407 is high then

the corresponding transistor switch turns on and connects the LED to

ground through the GND (pin 7, JP2) of the 7407.

This site was last updated 6th

August 2024.

This site was last updated 6th

August 2024.