Ammeter Project

The objective of the project was to create a stand-alone ammeter that could

be used to check the current draw of devices such as DC motors, in

particular to enable adjustment of the stepper driver current setting when

the details of the motor were not known (which is often the case when using

motors recovered from old equipment). While I have several multimeters that

can measure current, I wanted a separate unit because I have destroyed too

many devices when forgetting to turn the multimeter back to voltage!

The ACS712 current sensor module uses a hall-effect device to measure

current. It is available in three configurations, with maximum rated current

of 5 Amps, 20 Amps and 30 Amps.The 5A version was selected for this project

as it provided the required range with the maximum available resolution.

This project uses this module in conjunction with an Arduino Pro Mini and a

128x64 OLED display to create a digital ammeter.

Measuring Current.

The

ACS712 is a current sensing module that uses a low resistance shunt and a

hall-effect sensor to measure current. It interfaces to the Arduino

with an analog signal. The documentation for the ACS712 module

indicates that it only needs a connection to the Arduino and some

calculations in code to create the ammeter, but it turns out that the

process is not quite as simple as that.

The

ACS712 is a current sensing module that uses a low resistance shunt and a

hall-effect sensor to measure current. It interfaces to the Arduino

with an analog signal. The documentation for the ACS712 module

indicates that it only needs a connection to the Arduino and some

calculations in code to create the ammeter, but it turns out that the

process is not quite as simple as that.

The output of the module is a voltage that is proportional to the current

flowing through the device. The

module measures both AC and DC current, and for DC will report the current

as positive or negative. Therefore

the voltage output is centred around half of the module supply voltage. The

measured voltage represents amps per millivolt – for the 5-Amp device the

measurement is 0.185v per Amp. In order to convert this voltage to a current

reading the Arduino needs to know the supply voltage of the module, in order

to calculate the centre value and therefore the variance from this centre

value.

The Arduino has an ADC input available for measuring the supply voltage, but

this measurement depends, in turn, on knowing the supply voltage for the

Arduino. Whichever way it is arranged, a reference voltage seems to be

required.

The Arduino supply voltage is not suitable as a reference, as it can vary

from about 4.8v to a little over 5v, depending on where the nominal 5v is

being generated. The Arduino

ARef output cannot be used as it is not reliable at 5v if the Arduino supply

voltage dips below 5v, and it cannot be used at less than 5v as the ACS

module requires a supply of 5v. An external reference could be used, but the

circuitry becomes complex if it has to deal with a supply that might be less

than 5v. In each case the reference also has to deal with a varying load

from the ACS module.

This project avoids the problem of a reference voltage by using the nominal

5v supply and providing a calibration routine to adjust the calculation of

the module output voltage to the actual module supply voltage, without any

attempt to determine the absolute voltages.

The calibration occurs automatically at start up (on the assumption that no

load is connected to the ACS module) and whenever the user presses the

calibration button. This

procedure gives a reading that is good to within about 25mA, as far as I can

measure with typical hobbyist equipment. There has been comment that

the ACS module is not very accurate, but this is likely due to a failure to

include this calibration procedure.

The maximum resolution that is theoretically available can be calculated

from the available technical data. The

Arduino 10-bit ADC can create 1024 different values, with some uncertainty

at the 10th bit. At a supply voltage of 5v this translates to

about 5mv per count. A 5-Amp

module produces a voltage variation of 185mv per amp, so the Arduino can

detect about 37 counts per amp, or about 27mA, which agrees with the

measured results.

PARTS USED.

Arduino Pro Mini. I chose the Pro over the Nano because

I do not expect to be re-programming it and the USB interface could not be

justified. I have positioned it so that I can access the serial input pins

if required.

ACS712 current sensor module. Any

of the available variations of maximum rated amperage will do, but note

that the resolution is less at higher rated amps. The code provided

assumes the 5A version.

128x64 OLED display with I2C interface.

On/Off button. Salvaged from an old PC.

Momentary push button. Salvaged from an old PC.

Hookup wire and a scrap of perfboard.

9v Battery with clip and leads.

3D printed case with 3 3mm screws and knurled inserts.

DISPLAY.

The OLED display is a common, easily available item. For this project

I mounted it in a frame, because the unit is very fragile and it was going

to be subject to a lot of handling. I also inserted headers, but this

is not necessary - it is just as easy to solder the hookup wires direct to

the device. These displays are also available with an ISP interface -

either would work for this project, but the extra speed of ISP is not

required.

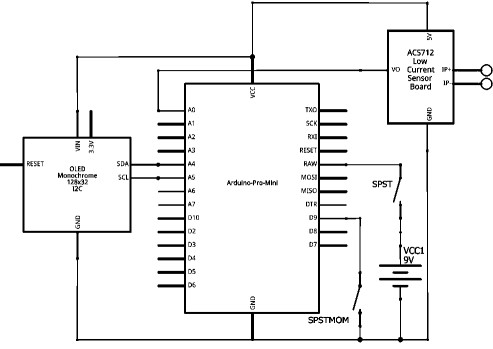

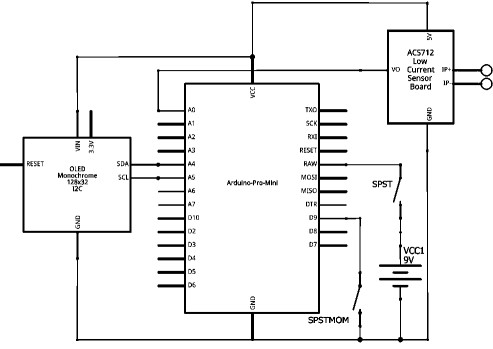

THE CIRCUIT

The 9v battery power is provided via the on/off switch to

VRaw of the Pro. Vcc from the Pro is distributed to the OLED and the

ACS. The ACS output is connected to analog input AO of the Pro, and

the SDA/SCL inputs for the OLED are driven from pins A4/A5 respectively of

the Pro. The calibration switch is a momentary connection of digital

pin 9 of the Pro to ground. The grounds of the three devices are all

tied to battery ground.

The 9v battery power is provided via the on/off switch to

VRaw of the Pro. Vcc from the Pro is distributed to the OLED and the

ACS. The ACS output is connected to analog input AO of the Pro, and

the SDA/SCL inputs for the OLED are driven from pins A4/A5 respectively of

the Pro. The calibration switch is a momentary connection of digital

pin 9 of the Pro to ground. The grounds of the three devices are all

tied to battery ground.

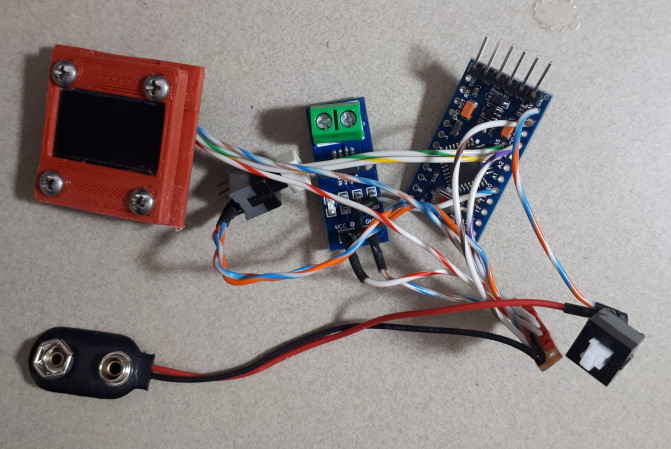

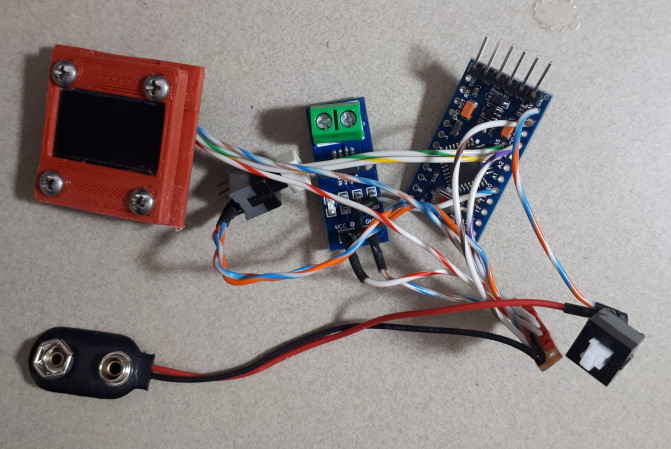

THE PROTOTYPE

After getting a

suitable layout for the components I wired everything together. The

hookup wire came from an old parallel printer cable. This wire is

easily tinned and soldered, the covering is very heat resistant, it is quite

flexible, and the multitude of colours means that the wire can indicate the

function of the connection, reducing the risk of mistakes. I used a

small strip of perfboard for the +5v and Gnd busses - the only parts of the

circuit with multiple connections.

After getting a

suitable layout for the components I wired everything together. The

hookup wire came from an old parallel printer cable. This wire is

easily tinned and soldered, the covering is very heat resistant, it is quite

flexible, and the multitude of colours means that the wire can indicate the

function of the connection, reducing the risk of mistakes. I used a

small strip of perfboard for the +5v and Gnd busses - the only parts of the

circuit with multiple connections.

Note that a prototyping board was not used for this project because the

components sit at different heights relative to the top surface, so it

would have been difficult to get everything at the correct level if they

were soldered to a single board.

The cover for the OLED was sourced from Thingiverse and scaled to

suit. There are many different sizes of OLED, so some experimenting

will probably be required to get just the right size. When adjusted

correctly the frame clamps the mounting surfaces between the front and

rear sections, without imposing any pressure against either the OLED

surface or the module substrate.

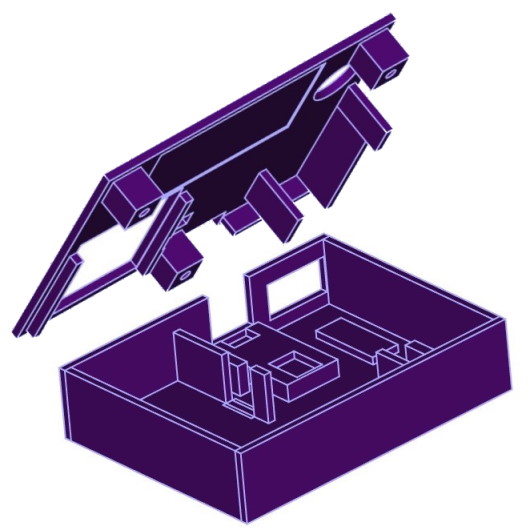

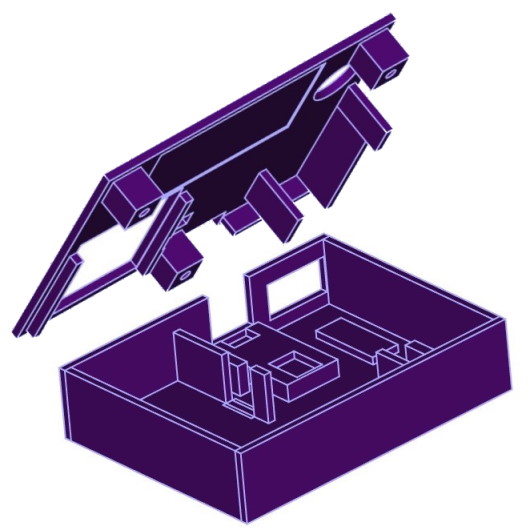

THE CASE

With the layout confirmed

I designed a case to suit. Only the ACS module and the perfboard

strip have mounting holes, so everything else sits on an offset on the

bottom of the case, and is positioned by dividing pieces or by the cutout

in the lid.

With the layout confirmed

I designed a case to suit. Only the ACS module and the perfboard

strip have mounting holes, so everything else sits on an offset on the

bottom of the case, and is positioned by dividing pieces or by the cutout

in the lid.

There is a cutout for the Pro programming pins

connections at the back, with a cover plate that can be pressed into place

to conceal them.

ASSEMBLED

With the components

inserted into the base a final test can be run before screwing on the lid. A

small piece of foam can be inserted at the front of the battery to stop it

moving, however it is actually held quite firmly between the lid and the

base. Note that not all ACS 712 modules include mounting holes to

allow it to be screwed down to the base - the terminals can require some

force to loosen if they have been overtightened, so a module that can be

firmly screwed down is probably preferred.

With the components

inserted into the base a final test can be run before screwing on the lid. A

small piece of foam can be inserted at the front of the battery to stop it

moving, however it is actually held quite firmly between the lid and the

base. Note that not all ACS 712 modules include mounting holes to

allow it to be screwed down to the base - the terminals can require some

force to loosen if they have been overtightened, so a module that can be

firmly screwed down is probably preferred.

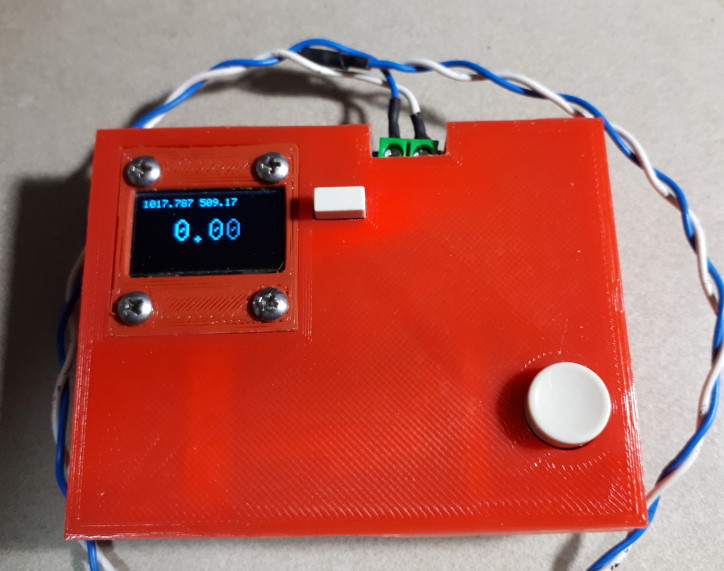

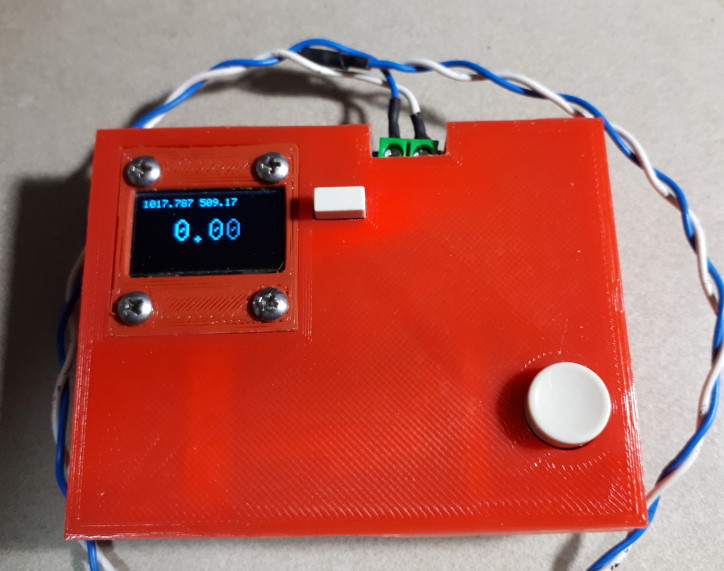

COMPLETED

The completed unit. The back

screws onto the face using 3off 3mm screws into knurled inserts set into

holes molded into the lid supports. Some components are glued to their

bases using a hot glue gun to make assembly easier. The OLED sits in a

frame that fits into the cutout in the lid and is supported on risers in the

base. The supports for the Pro and ACS are shaped to allow for the

solder points that extrude from the underside. The two switches straddle

their supports so that the pins help to locate them securely.

The completed unit. The back

screws onto the face using 3off 3mm screws into knurled inserts set into

holes molded into the lid supports. Some components are glued to their

bases using a hot glue gun to make assembly easier. The OLED sits in a

frame that fits into the cutout in the lid and is supported on risers in the

base. The supports for the Pro and ACS are shaped to allow for the

solder points that extrude from the underside. The two switches straddle

their supports so that the pins help to locate them securely.

CODE

The code for the ammeter is not complex, but it does

include a calculation to allow for calibration. This calculation occurs at

startup, so there is an assumption that no current source is attached the

the ACS terminals when the Arduino initialises.

The calibration code also executes whenever the user

presses the calibration button. This should only be done when there

is no load across the ACS terminals. This is not really required, as it is

almost as easy to turn the unit off and turn it on again, but it is

available as a quick check that the battery voltage has not changed

significantly.

The code uses the Ascii and AsciiWire versions of the

SSD1306 OLED libraries. These libraries provide all the

functionality that the application needs with much less overhead than the

standard libraries. The standard libraries could be substituted with a few

simple and obvious changes to the code (although some juggling might be

required to get the display laid out just right).

Confirm that the I2C address for your OLED is

correct. Adjust the number of samples if required (above about 100

it makes very little difference).

#include <Wire.h>

#include <SSD1306Ascii.h>

#include <SSD1306AsciiWire.h>

// OLED I2C address

#define I2C_ADDRESS 0x3C

SSD1306AsciiWire display;

boolean startup = true; // Flag to indicate auto calibrate

const int acsIn = A0; // Analog input for ACS reading

const int btnIn = 9; // Digital input for button press (active low).

void setup() {

Wire.begin();

Wire.setClock(400000L); // Adjust to suit OLED, if required.

pinMode(btnIn, INPUT_PULLUP);

pinMode(acsIn, INPUT);

//1 Serial.begin(9600); //Start Serial Monitor to display current read value on Serial monitor

display.begin(&Adafruit128x64, I2C_ADDRESS);

display.setFont(fixed_bold10x15);

display.clear();

display.println();

display.setLetterSpacing(2);

display.println(F("DIGITAL"));

display.print(F(" AMMETER"));

display.setFont(Adafruit5x7);

delay(1000); // Pause for 2 seconds

}

float cNominal = 1024.0; // ADC count max

float cCentre = 512.0; // ADC count centre (zero amps)

float vpc = 0; // Volts per count

void loop() {

unsigned int x = 0;

float vInput = 0.0, nSamples = 0.0, vAverage = 0.0, vAdjusted = 0.0, aCalculated;

for (int x = 0; x < 150; x++) { //Get 150 samples.

vInput = analogRead(acsIn); //Read current sensor values.

nSamples = nSamples + vInput; //Accumulate sample values.

delay (5); // Required ADC settling time.

}

vAverage = nSamples / 150.0; // Calculate average value.

//vpc is the assumed supply Vcc. The ADC value is referenced to this voltage.

//You must change the offset according to the input voltage

//0.185 (185mV) is output voltage change for 1A current ACS712-05 ( 5 Amp).

//0.100 (100mV) is output voltage change for 1A current ACS712-20 (20 Amp).

//0.066 (66mV) is output voltage change for 1A current ACS712-30 (30 Amp).

vpc = 5.00 / cNominal; // millivolts per ADC count. Adjust if Vcc is not 5v.

vAdjusted = (vAverage - cCentre) * +vpc; // Volts = Count * Volts per count.

aCalculated = vAdjusted / 0.185; // Amps = Volts / Volts per Amp.

// Re-calculate zero amps reading and max count at startup and at button press.

if ((digitalRead(btnIn) == LOW) || startup) {

cCentre = vAverage;

cNominal = cCentre * 2.0;

startup = false;

}

display.clear();

display.setFont(System5x7);

display.println(String(cNominal, 3) + ' ' + String(vAverage, 2));

//display.println();

display.setRow(2);

display.setFont(ZevvPeep8x16);

display.set2X(); // Double-size font

if (aCalculated >= 0.0) {

display.print(" " + String(aCalculated, 3));

}

else {

display.print(" " + String(aCalculated, 3));

}

display.set1X(); // Standard-size font.

display.setCursor(98,6);

display.println("Amps");

delay(50);

}

This site was last updated 18th August 2024.

With the layout confirmed

I designed a case to suit. Only the ACS module and the perfboard

strip have mounting holes, so everything else sits on an offset on the

bottom of the case, and is positioned by dividing pieces or by the cutout

in the lid.

With the layout confirmed

I designed a case to suit. Only the ACS module and the perfboard

strip have mounting holes, so everything else sits on an offset on the

bottom of the case, and is positioned by dividing pieces or by the cutout

in the lid. The

ACS712 is a current sensing module that uses a low resistance shunt and a

hall-effect sensor to measure current. It interfaces to the Arduino

with an analog signal. The documentation for the ACS712 module

indicates that it only needs a connection to the Arduino and some

calculations in code to create the ammeter, but it turns out that the

process is not quite as simple as that.

The

ACS712 is a current sensing module that uses a low resistance shunt and a

hall-effect sensor to measure current. It interfaces to the Arduino

with an analog signal. The documentation for the ACS712 module

indicates that it only needs a connection to the Arduino and some

calculations in code to create the ammeter, but it turns out that the

process is not quite as simple as that.  The 9v battery power is provided via the on/off switch to

VRaw of the Pro. Vcc from the Pro is distributed to the OLED and the

ACS. The ACS output is connected to analog input AO of the Pro, and

the SDA/SCL inputs for the OLED are driven from pins A4/A5 respectively of

the Pro. The calibration switch is a momentary connection of digital

pin 9 of the Pro to ground. The grounds of the three devices are all

tied to battery ground.

The 9v battery power is provided via the on/off switch to

VRaw of the Pro. Vcc from the Pro is distributed to the OLED and the

ACS. The ACS output is connected to analog input AO of the Pro, and

the SDA/SCL inputs for the OLED are driven from pins A4/A5 respectively of

the Pro. The calibration switch is a momentary connection of digital

pin 9 of the Pro to ground. The grounds of the three devices are all

tied to battery ground.  After getting a

suitable layout for the components I wired everything together. The

hookup wire came from an old parallel printer cable. This wire is

easily tinned and soldered, the covering is very heat resistant, it is quite

flexible, and the multitude of colours means that the wire can indicate the

function of the connection, reducing the risk of mistakes. I used a

small strip of perfboard for the +5v and Gnd busses - the only parts of the

circuit with multiple connections.

After getting a

suitable layout for the components I wired everything together. The

hookup wire came from an old parallel printer cable. This wire is

easily tinned and soldered, the covering is very heat resistant, it is quite

flexible, and the multitude of colours means that the wire can indicate the

function of the connection, reducing the risk of mistakes. I used a

small strip of perfboard for the +5v and Gnd busses - the only parts of the

circuit with multiple connections.

With the components

inserted into the base a final test can be run before screwing on the lid. A

small piece of foam can be inserted at the front of the battery to stop it

moving, however it is actually held quite firmly between the lid and the

base. Note that not all ACS 712 modules include mounting holes to

allow it to be screwed down to the base - the terminals can require some

force to loosen if they have been overtightened, so a module that can be

firmly screwed down is probably preferred.

With the components

inserted into the base a final test can be run before screwing on the lid. A

small piece of foam can be inserted at the front of the battery to stop it

moving, however it is actually held quite firmly between the lid and the

base. Note that not all ACS 712 modules include mounting holes to

allow it to be screwed down to the base - the terminals can require some

force to loosen if they have been overtightened, so a module that can be

firmly screwed down is probably preferred.

The completed unit. The back

screws onto the face using 3off 3mm screws into knurled inserts set into

holes molded into the lid supports. Some components are glued to their

bases using a hot glue gun to make assembly easier. The OLED sits in a

frame that fits into the cutout in the lid and is supported on risers in the

base. The supports for the Pro and ACS are shaped to allow for the

solder points that extrude from the underside. The two switches straddle

their supports so that the pins help to locate them securely.

The completed unit. The back

screws onto the face using 3off 3mm screws into knurled inserts set into

holes molded into the lid supports. Some components are glued to their

bases using a hot glue gun to make assembly easier. The OLED sits in a

frame that fits into the cutout in the lid and is supported on risers in the

base. The supports for the Pro and ACS are shaped to allow for the

solder points that extrude from the underside. The two switches straddle

their supports so that the pins help to locate them securely.