AC Motor Controller

A project that mounts an AC motor speed controller in a box that

incorporates a standard Australian power point for use with any device

that uses a standard 240V plug. This controller can be used with

loads such as an incandescent light (or LED lights that are marked as

compatible with a dimmer) or as a speed controller for general-purpose

(ie, not induction) AC motors.

Parts:

AC Motor Speed Control Module

AC Wall Socket with mounting screws

Power cord, grommet and ferrite ring

Switch, DPST 240VAC 5A

Fuse holder and fuse, 240VAC 5A

Slide terminals, ferrules, wire and cable tie.

The

AC Motor Speed Controller is rated at 2000W for

110-250 volt input up to 25A. The maximum rating would be

sustainable for very short bursts only, but for things like fans and small

motors it is quite suitable. In this case it is intended for a

small AC motor mounted with a grinding wheel, and the components

(including fuse) are rated for a maximum 5A at 240VAC to keep performance

well within the rated maximum. Note that the minimum available

output voltage should be adjusted to ensure that any attached motor is not

driven at less than its stall voltage.

The

AC Motor Speed Controller is rated at 2000W for

110-250 volt input up to 25A. The maximum rating would be

sustainable for very short bursts only, but for things like fans and small

motors it is quite suitable. In this case it is intended for a

small AC motor mounted with a grinding wheel, and the components

(including fuse) are rated for a maximum 5A at 240VAC to keep performance

well within the rated maximum. Note that the minimum available

output voltage should be adjusted to ensure that any attached motor is not

driven at less than its stall voltage.

As this is a 240V project construction must be to a suitable

standard. Wiring must be mains rated and all terminals should be

shrouded. The connection to the socket should use crimped ferrules,

to eliminate the risk of stray wires. The mains input lead

should be grommetted and firmly secured. The case must be securely

closed - this project uses the wall socket securing screws to close the

case, which also means that there are no external exposed metal parts, and

the securing screws are not exposed in the interior. It is particularly

important that the frame supporting the potentiometer cannot contact any

of the internal wiring, as that part is potentially exposed through the

shaft of the pot.

The fuse used in the project is only accessible with a screwdriver, and

also holds the fuse firmly in the cap so that the potentially live end of

the fuse is not exposed when the cap is undone and being removed.

There are many panel-mounted fuses available that do not have this

important protection even though they are mains rated. Note that some fuse

holders include this protection only if they are wired with the correct

polarity.

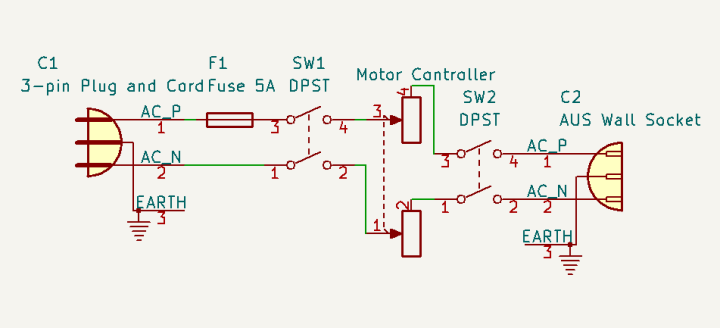

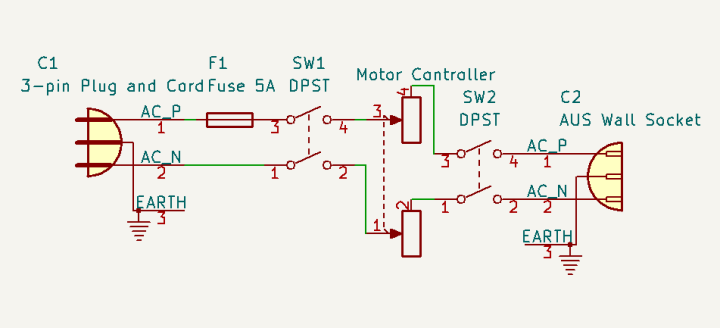

Schematic

The

unit incorporates a switch for the source as well as the output, so that the

supply to the controller can be switched off when there is no device

attached.

The

unit incorporates a switch for the source as well as the output, so that the

supply to the controller can be switched off when there is no device

attached.

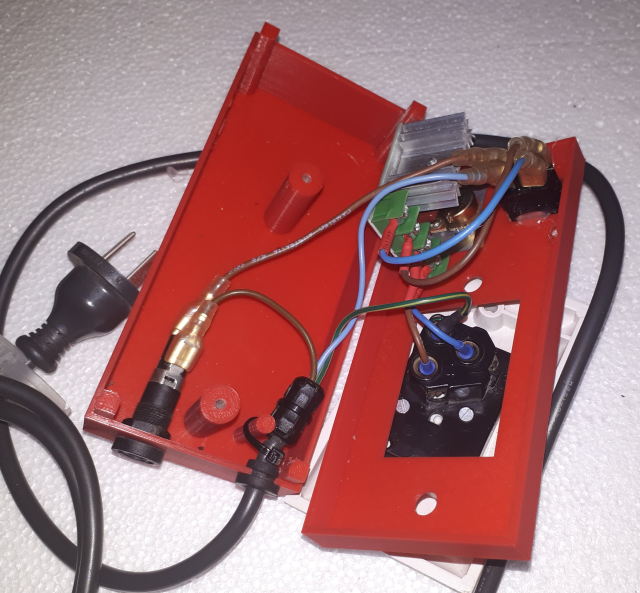

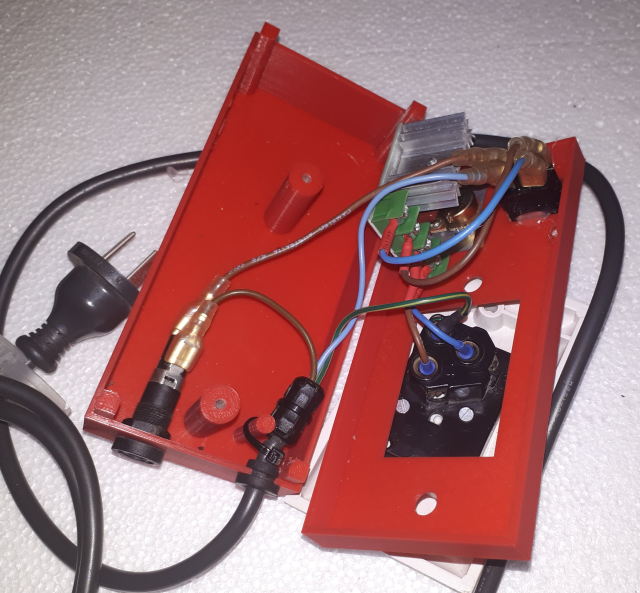

Assembled

The wall socket is mounted to the front surface of a 3D-printed

case. The controller and supply switch are mounted through the front

face, while the fuse and input cord mounting are fitted to the back.

The halves of the case are held together by the screws that also secure

the wall socket. The 240VAC earth lead is secured by cable ties to a

pillar provided for that purpose. Note that this lead must have the

most slack of the 3 leads from the power cord. A ferrite bead will

help in preventing switching noise being fed back into the mains - there

is room available for a bigger inductor if noise is a problem (as used in

this example).

As Used

The driver has been used for a small AC motor mounted with a grinding

disc, and also for a brushed 230VDC motor via a rectifier.

This page last updated 18 August 2024

The

AC Motor Speed Controller is rated at 2000W for

110-250 volt input up to 25A. The maximum rating would be

sustainable for very short bursts only, but for things like fans and small

motors it is quite suitable. In this case it is intended for a

small AC motor mounted with a grinding wheel, and the components

(including fuse) are rated for a maximum 5A at 240VAC to keep performance

well within the rated maximum. Note that the minimum available

output voltage should be adjusted to ensure that any attached motor is not

driven at less than its stall voltage.

The

AC Motor Speed Controller is rated at 2000W for

110-250 volt input up to 25A. The maximum rating would be

sustainable for very short bursts only, but for things like fans and small

motors it is quite suitable. In this case it is intended for a

small AC motor mounted with a grinding wheel, and the components

(including fuse) are rated for a maximum 5A at 240VAC to keep performance

well within the rated maximum. Note that the minimum available

output voltage should be adjusted to ensure that any attached motor is not

driven at less than its stall voltage. The

unit incorporates a switch for the source as well as the output, so that the

supply to the controller can be switched off when there is no device

attached.

The

unit incorporates a switch for the source as well as the output, so that the

supply to the controller can be switched off when there is no device

attached.